The Challenge

A manufacturer in the chemical processing industry (CPI) approached Marco Rubber & Plastics with a sealing problem. The manufacturer was having issues with a failing seal that was currently used in a high-pressure, gaseous application. It was clear that rapid gas decompression resistance was needed.

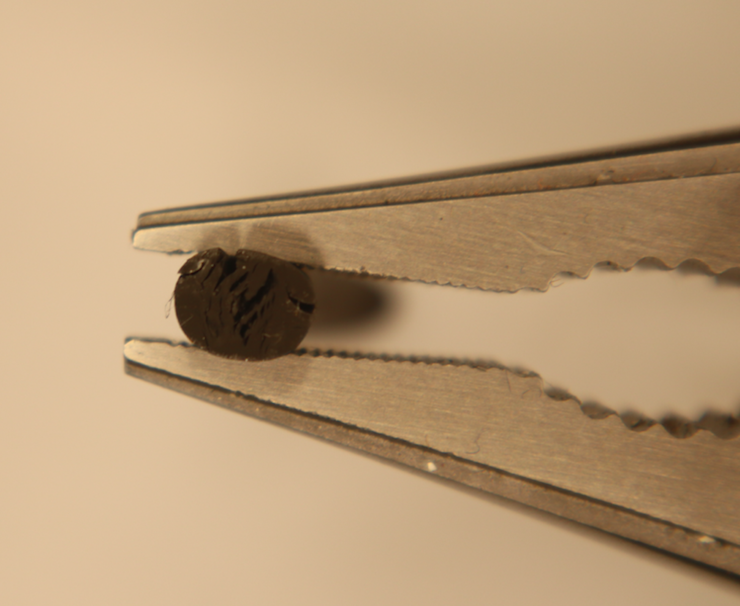

Explosive decompression o-ring damage is a common reason for failure in such circumstances. Visually, this is indicated when the sealing surface is blistered or marked with deep splits. In the worst examples, the sealing surface is completely ruptured. Rapid Gas Decompression (RGD) resistance is needed when seals are exposed to high-pressure gas at elevated temperatures (or extremely low temperatures) for a prolonged period of time. At high pressures, the gas compresses and can permeate into the polymer. When that high pressure is reduced, the gas expands and is forced out of the material.

In addition to those concerns, the manufacturer was using a seal — made from a 75A FKM material with a very large ID (interior diameter) — that was spliced and vulcanized. While seeking a material or product that could meet the demands of the application, the manufacturer also sought a solution that would remain in service twice as long as their current seal.

The Solution

The engineering team at Marco Rubber inspected the customer’s sample using visual and mechanical tests and noticed several issues right away.

First, there were cracks and splitting along the length of the o-ring. We cut the o-ring to view the cross-section and saw more splitting throughout the interior as well. Knowing the application involved high-pressure gases, it was concluded that the cracks were a result of severe explosive decompression. The proper seal would need more rapid gas decompression resistance.

Second, the spliced and vulcanized joint on the seal was split cleanly. This is normally an indication of a bad or incomplete bond, but with the evidence of explosive decompression throughout the o-ring, it was determined that the clean split at the joint was also a result of that effect. The pressurized gas permeates and evacuates the material through the path of least resistance, which in this case was the joint. Eliminating the weakness of the joint became a priority.

The Result

Marco Rubber’s engineering team discussed our findings with the customer and proposed using our V1090 compound, which is a 90A durometer FKM that is NORSOK M710 certified for rapid gas decompression resistance. We also proposed our proprietary method of continuously molding the o-ring as opposed to splicing and vulcanization to eliminate the vulnerable joint.

With engineering choices addressing the two biggest issues with the implementation of the seal within the application, the customer has found that our solution is able to remain in service over five times as long as their original seal.

Connect with Marco Rubber today to learn more about our capabilities in crafting high-pressure or CPI sealing solutions that need rapid gas decompression resistance.