Marco supplies fully molded O-Rings and other basic seals often without tooling fees for custom sizes less than 35” diameter. When a very small quantity of custom sized seals are needed quickly, often spliced and vulcanized or bonded methods are most practical. Also, non-traditional molding methods are required to produce giant oversized seals with diameters over 35” diameter. We have summarized the various methods to help determine the best option for your application. Dimensional tolerances vary by size and manufacturing method. All of these methods are non-returnable so please contact us if additional details are required.

Continuous Molding

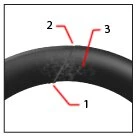

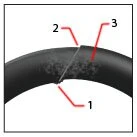

Proprietary molding method that typically results in nearly same quality as traditional fully molded techniques with almost undetectable joints. Investing in continuously molded method will increase the consistency of higher performance sealing applications. Best option for large and critical applications like in Vacuum, LCD, Solar equipment manufacturing with low seal compression force. Possible slight parting line and flash misalignment and variable surface finish at the mold transfer points (Figure 1). ID dimensional tolerances per quote.

Figure 1

Tooling Cost

Depending on CS

Typical Lead Time

5 to 12 Weeks

Advantages

- Best option for high performance, dynamic, gas, pressure and vacuum applications over 35” Diameter

- Performance similar to fully molded

- Proprietary method yields consistent quality

Disadvantages

- Highest cost due to time and scrap rate

- Longer lead times

Serpentine Fully Molded

Traditional fully molded techniques are performed with non-traditional gland configuration. Glands are typically snake shaped to allow more linear space. Besides the high mold cost, the main disadvantage is the seal can relax in the shape of the mold which makes installation more challenging and increases potential for leaking (Figure 1). Compression molding parting line and flash may also be an issue since typically hand trimmed due to the overall size. Continuous Molding method has replaced this method in most situations.

Figure 1

Tooling Cost

Depending on CS

Typical Lead Time

3 to 8 Weeks

Advantages

- Fully molded in serpent shape with no joints

- Can make larger ID than press size

Disadvantages

- High mold/tool costs

- Tight molded curve radii memory can increase leak potential

- Limitation on max ID size

- Not recommended for sealing gases, high pressure or dynamic seals

Molded Joint

Partially cured molded cord is joined and molded under pressure and high temperature in a tool/fixture. Depending on size multiple joints could be used. The finished seal is then placed in a high temperature post cure oven to complete the cure. After the o-ring is fully cured, it is de-flashed and buffed if required. ID dimensional tolerances per quote.

- Potential slight over-fill at joint (Figure 1 #1)

- Potential slight under-fill at joint could lead to leaks in some applications (Figure 1 #2)

- Parting line and flash can be misaligned at joint (Figure 1 #3)

- Buffing at the joint can yield variable surface finish from the rest of the part (Figure 1 #4)

Figure 1

Tooling Cost

N/A

Typical Lead Time

2 to 8 Weeks

Advantages

- No mold/tool cost

- Option for prototyping and basic applications with > 15% compression-squeeze

- Performance can be similar to fully molded

Disadvantages

- Inconsistent quality

- Occasional slight under-fill or over-fill at joint increases leak potential

- Parting line and flash can be misaligned and buffed at joint

- Multiple joints can be required

- Not recommended for vacuum or high pressure

Precision Vulcanization

Fully cured extruded cord is typically cut to length with a 45 degree angle scarf cut ends. A proprietary process is performed to bond the ends with a rubber and adhesive mixture that results in a much cleaner joint than Standard methods. The consistently cleaner joint allows for better sealing with less leak potential which can be used in higher performance applications. Good joint tensile strength can be achieved with Buna-N, Neoprene and EPDM, reasonably good with Viton and only fair strength can be expected with Silicone. Great for prototyping before migrating to Continuous Molding method. ID dimensional tolerances per RMA Table 18, S1 Precision or better.

- Potential for slight adhesive excess at joint (Figure 1 #1)

- Potential slight misalignment (Figure 1 #2)

- Buffing at the joint can yield variable surface finish from the rest of the part (Figure 1 #3)

Figure 1

Tooling Cost

N/A

Typical Lead Time

1 to 21 Days

Advantages

- Best value for prototyping and basic applications

- Proprietary method yields consistent quality

- Angled joint increases bond surface area and strength

Disadvantages

- Higher cost than standard vulc

- Lead times can be longer than standard vulc

- Potential for slight excess adhesive, misalignment and buffing at joint

- Not recommended for vacuum, high pressure or dynamic seals

Standard Vulcanization

Fully cured extruded cord is typically cut to length with a straight 90 degree or 45 degree angle scarf cut ends depending on the material type and thickness. The ends are treated with a mixture of uncured rubber and adhesive and placed in a tool fixture to heat and cure the joint. Once removed from the fixture the joint might be buffed but imperfections could remain that can cause leaking in some applications thus recommended for very basic short term non-critical applications. Joint quality can vary as they are produced by hand.

Good joint tensile strength can be achieved with Buna-N, Neoprene and EPDM, reasonably good with Viton and only fair strength can be expected with Silicone. ID dimensional tolerances per RMA Table 18, S2 Commercial or better.

- Potential excessive adhesive at joint (Figure 1 #1)

- Potential misalignment (Figure 1 #2)

- Buffing at the joint can yield variable surface finish from the rest of the part (Figure 1 #3)

Figure 1

Tooling Cost

N/A

Typical Lead Time

1 to 21 Days

Advantages

- Rubber based adhesive

- Flexible compressible joint

- Angled or Straight joint depending on material and thickness

- Only for basic static, low pressure, short term applications

Disadvantages

- Inconsistent quality

- Angled or Straight joint depends on material and thickness

- Potential excessive adhesive at joint

- Potential misalignment

- Only for basic static, low pressure, short term applications

Renderings displayed on this page are exaggerated to describe potential issues.

Have Questions About Your Specific Application?

Connect With an Expert

- Expert product, application and design assistance

- Trusted by 14,000+ customers

- Fast response (usually within hours)