The Challenge

A long-term customer of Marco Rubber & Plastics that manufactures valves and control components came to us with a difficult sealing dilemma. The customer required the seal in their application to withstand 600° F and 1,000 PSI (pounds per square inch) of hot air under dynamic conditions. However, the typical metal spring energized seal that would be employed in such a scenario is good for only around 500° F. This required Marco Rubber to find a custom sealing solution that not only addressed the high-temperature issue but also chemical processing industry (CPI) concerns as well to deal with the aggressive media (in this case hot air) in the environment.

The Solution

With extensive experience dealing with high-temperature plastic and elastomeric seals, Marco Rubber’s engineering department went to work designing a custom sealing solution. Marco Rubber settled on a custom design made with a special high-temperature PTFE (Polytetrafluoroethylene) and high-temperature spring materials capable of withstanding temperatures up to 600° F continuously.

The Result

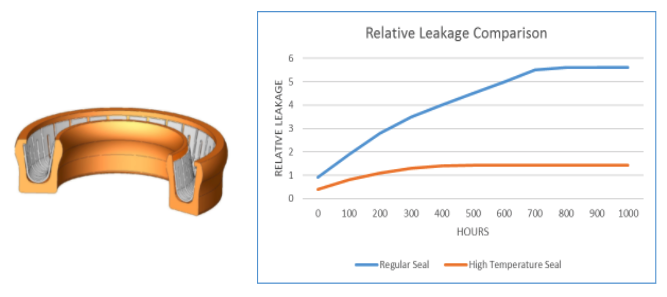

The custom-designed, high-temperature seal was tested against a regular spring energized PTFE seal. Marco Rubber’s custom seal had lower leakage, less permanent deformation, and achieved higher overall performance.

The custom sealing solution scored relative leakage at less than a third of that from the regular seal, and ultimately provided another example of Marco Rubber’s ability and expertise to deliver tailored answers to demanding applications for customers.

Connect with Marco Rubber today to learn more about our capabilities in crafting high-temperature or CPI sealing solutions.