Spring Energized Seals & Metal O-Rings for Extreme Environments

Spring Energized Seals Offer High Performance in Tough Environments

Spring energized seals and metal o-rings offer the highest sealing performance in the harshest industrial environments. These seals feature outstanding chemical compatibility, low friction, long service life and durability in low temperature or cryogenic applications. Typical uses include compressed gas waterless fracking seals, LPG, and liquid nitrogen, as well as rotary, reciprocating, and oscillatory motions. Spring energized seals and metal o-rings deliver the ultimate sealing performance in a wide range of demanding environments.

Marco Rubber has the world's largest o-ring inventory network and can use direct purchasing power to offer spring energized seals and metal o-rings at the lowest possible cost. Typically, custom spring energized seals and metal o-rings can be produced with no additional tooling fees within just a few weeks. Order online from Marco Rubber today for fast shipping and reliable service.

Spring energized seals and metal o-rings from Marco Rubber include

- MSE® seal, Variseal®, and FlexiSeal® alternatives

- Standard seals that operate up to 3,000psi and custom seals up to 60,000psi

- Standard seals that operate between -280°F and 500°F and custom seals from -400°F to 600°F

- Rod and Piston Inside and Outside Pressure and unidirectional sealing configurations

- A wide range of high-performance sealing materials

- Metal spring energized PTFE seals for extreme environments

Seal Types and General Capabilities

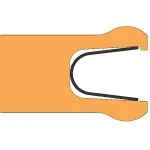

Finger Spring

Applications

This seal type is mainly intended to be used in dynamic applications. This seal has a balance of good sealability, low friction and long service life. Can be used for up to 250 ft/min. surface speed. Available in piston, rod and face seal configurations.

Operating Temperature Min: -73°C (-100°F)

Operating Temperature Max: 315°C (600°F)

Sealability with Helium: Good

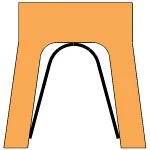

Coil Spring

Applications

This seal type is designed for static or slow dynamic applications, sacrificing some flexibility for improved sealability. Available in piston, rod and face seal configurations.

Operating Temperature Min: -173°C -280°F

Operating Temperature Max: 260°C 500°F

Sealability with Helium: Better

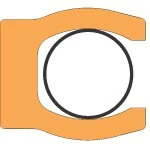

Double Coil Spring

Applications

This seal type is designed for static applications only. The high spring load ensures better sealability than a single spring seal. This type of seal is specifically recommended for cryogenic applications. Available in piston, rod and face seal configurations.

Operating Temperature Min: -268°C -450°F

Operating Temperature Max: 260°C 500°F

Sealability with Helium: Best

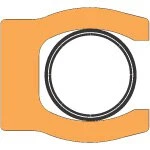

O-Ring Energized

Applications

This seal type is suitable for static and dynamic applications. The o-ring is energized is used in cases when the metal spring cannot be used for compatibility reasons. Available in piston, rod and face seal configurations.

Operating Temperature Min: *

Operating Temperature Max: *

Sealability with Helium: Good

The information on this page is to the best of our knowledge accurate and reliable. However, Marco Rubber makes no warranty, expressed or implied, that parts manufactured from this material will perform satisfactorily in the customer's application. It's the customer's responsibility to evaluate parts prior to use.

The temperature ranges presented on this page are approximations for dry air service only and should not be used to determine design specifications or end-use temperature limits. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. The most practical way of determining an end-use temperature range is testing in the actual application conditions. Consult a Marco Engineer for more details.

Jacket Materials Available

- Virgin PTFE: Recommended for most static applications

- Graphite Filled PTFE: Recommended for dynamic applications

- Carbon Filled PTFE: Recommended for higher pressure dynamic applications

- Polymer Filled PTFE: Recommended for dynamic applications and long service life

- UHMW-Polyethylene: Recommended for abrasive media at temperatures up to 200°F

- Hytrel: Recommended for abrasive media at temperatures up to 315°F

- PEEK: High strength plastic recommended for temperatures up to 500°F

- Other Materials: Many more PTFE compounds and other plastics available. Contact Marco Rubber's engineering team for specific information.

Spring Materials Available

- 301 SS: Recommended for general applications. For temperatures up to 500°F

- 302 SS: Recommended for general applications. For temperatures up to 500°F

- 304 SS: Recommended for general applications. For temperatures up to 450°F

- 316 SS: Recommended for general applications. For temperatures up to 400°F

- Elgiloy: Greater chemical and temperature resistance. Meets NACE MR-01-75. For temperatures up to 600°F

- 17-7 PH SS: Standard for Coil springs for general applications. For temperatures up to 500°F

- Inconel 718: For extreme temperatures up to 600°F

- Other Materials: Nitrile, FKM, FFKM are also available for use as energizer materials.

Contact Marco's engineering for specific material information or for assistance regarding applications requiring higher temperatures and/or higher pressures.

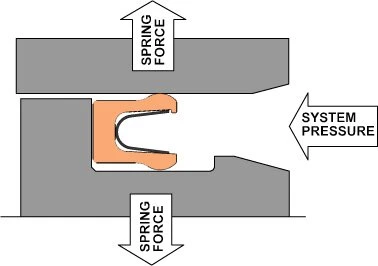

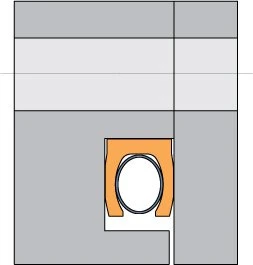

Examples of Seal Configurations

Many more custom designed configurations are available to meet a wide range of hardware configurations and applications.

Gland Configurations

Radial Gland

Flange Gland

Seals available for Piston, Rod, Flange Seals for Inside & Outside pressure as well as custom gland configurations. Visit our Seal Gland Design Guide for more information.

Typical Equipment

- Valve stems

- Valve bodies

- Flanges

- Ball valve seats

- Pumps

- Swivels

- Turbo pumps

- Joints

- Compressors

- Turbo Expanders

- Cryogenic seals

- Waterless fracking

Spring Energized O-Rings

PFA or FEP polymer encapsulating a 300 series stainless steel spring. Excellent chemical resistance and a temperature capability from -420°F to +500°F.

Spring Energized O-rings are typically available in the following cross-sections and can be made to match standard AS568A o-ring sizes:

- 0.070” cross-section

- 0.103 cross-section

- 0.139 cross-section

- 0.210 cross-section

- 0.275 cross-section

MSE® is a registered trade name of Greene, Tweed & Co. Variseal® is a registered trade name of Trelleborg.

Flexiseal® is a registered trade name of Parker Seal. PTFE is a registered trade name of DuPont Corp.