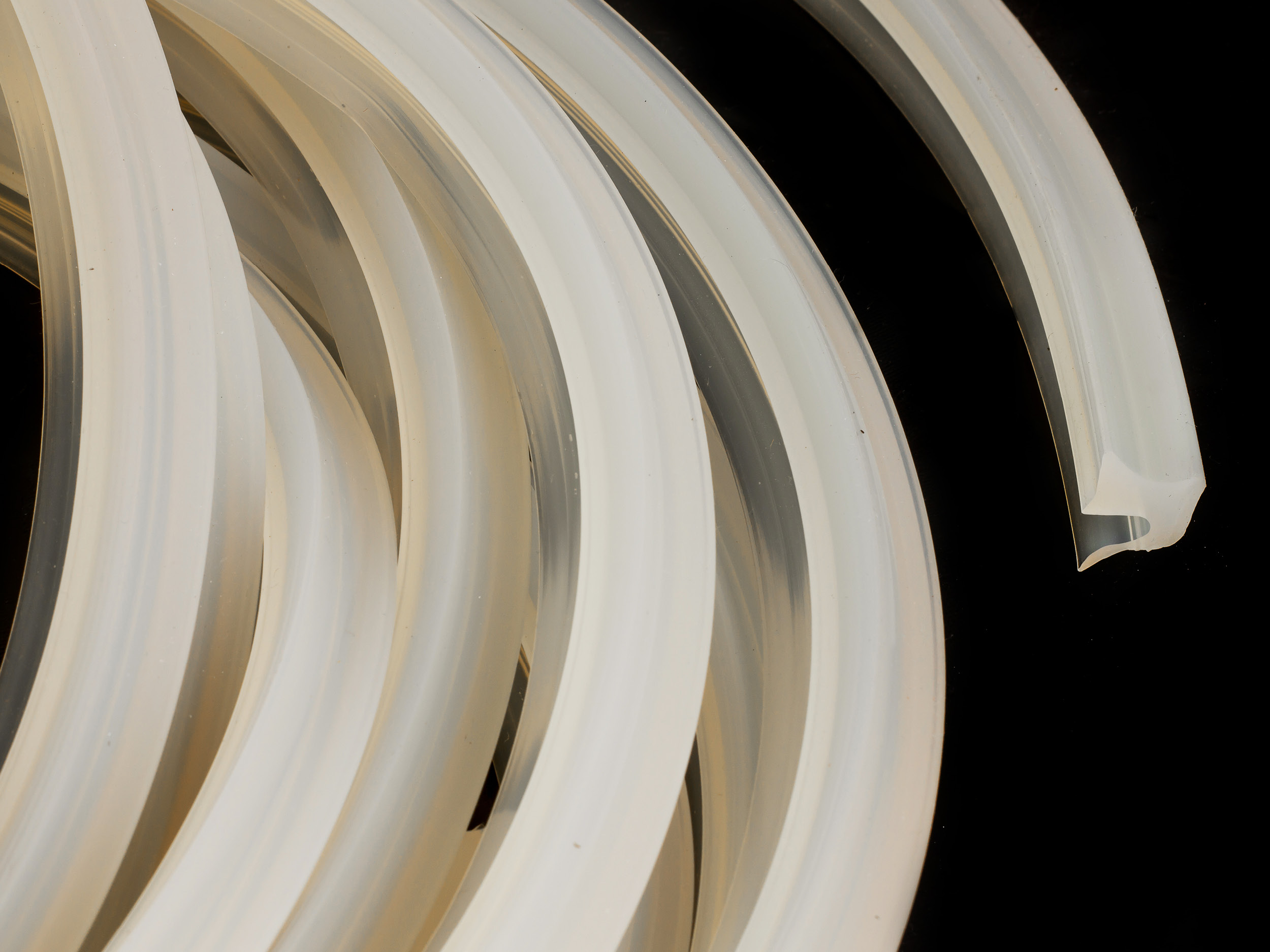

Is a Silicone Seal Right for Your Application?

Anyone who has ever tried to find a sealing solution knows that the number of options is limitless. But which option is actually the best fit for your application?

One of the primary options is silicone, so let’s find out if it is the solution for which you have been looking.

Silicone is an inorganic, common synthetic polymer. The family “silicone” refers to a number of polymers made up of repeating units of siloxane. Siloxane’s main chain is essentially a pattern of alternating silicon(Si) and oxygen(O) atoms.

Silicone is very versatile and offers a number of benefits including resistance to:

- extreme temperatures, including heat and cold (-75° to 450°F),

- ozone,

- UV,

- weather,

- chemical,

- oil,

- water steam,

- and corona discharge.

Silicone is also suitable for use with both acids and alkalis.

One of the amazing features of silicone is its ability to be morphed to fit many situations. For example, Marco Rubber offers silicone products suitable for a wide range of specialty applications and industries. We have compounds for almost every need, such as:

- Flame retardant grades.

- Electrically conductive materials.

- Extreme high and low temperature grades.

- Platinum cured formulations.

We often develop formulations uniquely designed to meet individual customer specifications, but more on that later. As a baseline, we offer a wide range of silicone forms to fit almost any application, including:

- compression molding and injection molding using liquid silicone rubber (LSR) or high temperature vulcanized (HTV),

- solid silicone rubber extrusions,

- and expanded closed-cell silicone rubber extrusions (also known as silicone sponge or foam).

What form of silicone will work best for your organization will depend on your industry and applications. Let’s take a deeper look at some industries that commonly use silicone.

Medical & Pharmaceutical

One of the most important components of the medical and pharmaceutical industry is cleanliness in accordance with regulatory compliance. We offer silicone compounds that are USP Class VI compliant and are, therefore, suitable for use when the product comes in contact with humans.

Our supply chain includes an ISO Class 7 and Class 8 clean room according to ISO 14644-2:2015 standards.

Silicone can also be adjusted to many scenarios beyond essential regulatory requirements. For instance, our silicone team once developed a formulation to satisfy very specific biocompatibility testing requirements that went beyond USP Class VI guidelines.

Food & Beverage

Silicone can be FDA 21 CFR Section 177.2600 compliant and, thus, suitable for contact with food.

This incredible material is also an excellent choice for those in the dairy and agriculture industry. Silicone can be made into extreme high tear resistant tubing. This tubing has an ultrasmooth inner surface with antimicrobial properties that inhibits growth of harmful bacteria.

We also offer formulations suitable for NSF submission. For example, we have silicone formulations that meet NSF-61 standards for potable water systems for public use and consumption.

Automotive

The automotive industry also faces a large number of strict regulatory requirements to keep end users safe and protect the company from recalls. Our silicone comes in ASTM D2000 FC / FE / GE compliant compounds.

Aviation, Space, & Defense Industries

Silicone compounds can meet Aeronautical Material Specification (AMS) standards for heat and weather/environmental resistance for silicone rubber, including SAE-AMS-3302 / 3303 / 3304 / 3305.

When it comes to specific accreditation, such as Boeing BMS 1-60 and Airbus ABD0031, silicone compounds can also be suitable.

Silicone is low-weight, non-flammable with self-extinguishing silicone sponge or foam. With high heat-resistant properties, silicone is suitable for a number of aviation, space, and defense applications.

Moreover, if you work with Marco Rubber we can provide full material certification for other aerospace MIL spec standards.

Rail Industry

The rail industry requires flame retardant or self-extinguishing and low smoke, low toxic fume formulations for both solid and silicone sponge. Good news: we make that simple.

We also offer compounds that are compliant with EN45545-2 (European fire safe materials standard), UL94V-0 (US fire standard), and NFPA 130 (US flame and smoke standard specifically for the rail industry).

Is Silicone Right for You?

As demonstrated, silicone is a widely versatile material that can be used in many applications while meeting applicable regulatory requirements.

There are a few instances where silicone would not be right for your application. For example, silicone would not be right for you if you need:

- high tensile strength,

- high tear resistance,

- high dynamic resistance,

- high abrasion resistance,

- use with fuels or petroleum-based oils,

- or high impermeability.

But we believe there is one key factor to consider when deciding if silicone is right for you or not: the manufacturer.

Your silicone manufacturer will make or break the experience of using silicone. They will be able to provide you with needed documentation for applicable regulatory requirements. They will help you identify appropriate sizing or creative solutions. They will be able to help you develop a specialized or custom solution for harsh sealing applications.

For example, when a customer was developing a new design of an aircraft water valve, they came to us. They needed a diaphragm that was dimensionally stable but flexible and FDA compliant. Originally, they had worked with a traditional fabric reinforced material, but it was too stiff for the desired functional performance.

So we went to work.

We proposed a fiber-reinforced, FDA compliant nitrile rubber material. With some additional design modifications, the resulting diaphragm performed for over 10 years.

That’s the difference when you work with a collaborative partner invested in your success.

Don’t settle for less: work with Marco Rubber.

We are always expanding to bring more solutions and more experts into the fold to provide top-of-the-line and innovative solutions to our customers.

Is Marco right for you? Let’s chat and find out.