The Challenge: Two Performance Needs, One Opportunity

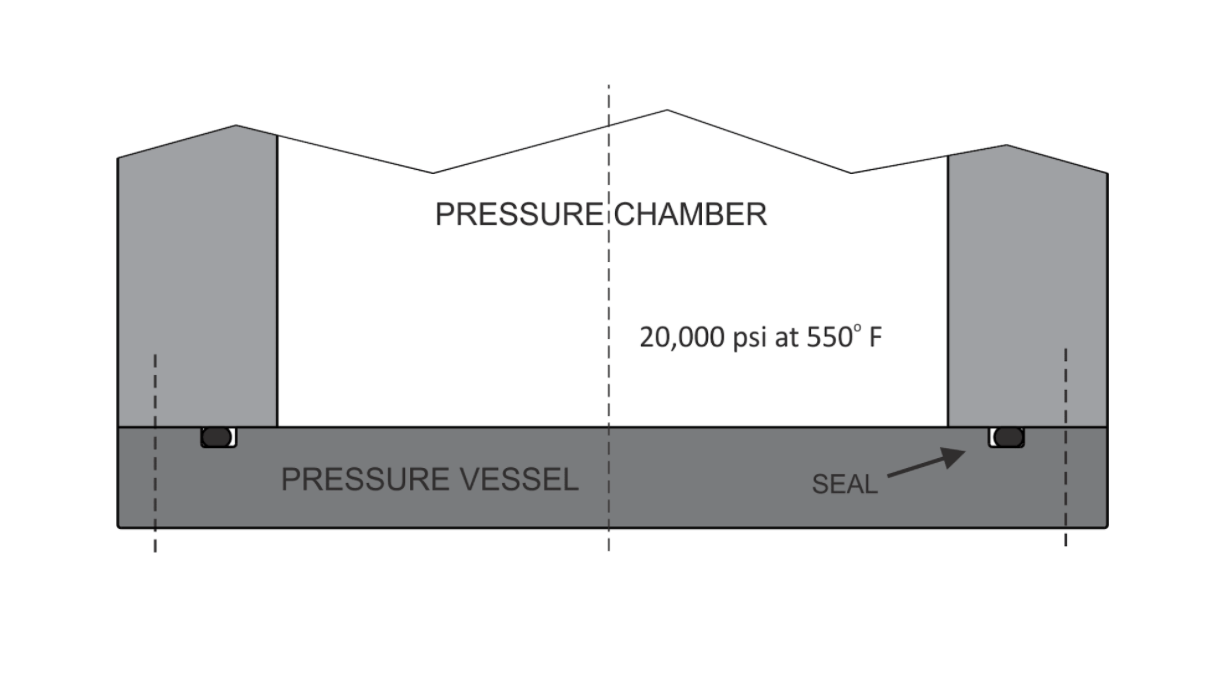

A manufacturer of high-pressure vessels approached Marco Rubber & Plastics for a recommendation on a high-temperature, high-pressure seal for a vessel that required performance in both areas.

Application Requirements

The ideal high-temperature, high-pressure seal would need to perform under a variety of challenging conditions and would require a general yet highly advanced material solution:

- Resist high pressures of up to 20,000 psi

- Perform at temperatures as extreme as 550 ºF

- Fit into a regular o-ring groove with no back-up rings

The Solution: A Custom High-Temperature, High-Pressure Seal

The Marco Rubber & Plastics engineering team recommended a proprietary high-temperature, high-pressure seal: Markez Z1028 — an in-house-designed perfluoroelastomer (FFKM) compound that is capable of withstanding temperatures up to 600 ºF. Our team also recommended some changes to the hardware to prevent the formation of an extrusion gap on the metal joints when exposed to high pressures.

The Result: The Right High-Pressure Seal for the Job

Our seal solution more than met the demands of the application while also providing the necessary pressure resistance. And thanks to our team’s ability to create custom sealing solutions for virtually any need, we were able to develop a solution that worked with the o-ring groove available.

After making the recommended changes to the hardware, the manufacturer of the pressure vessel installed and tested the parts at maximum pressure and temperature. The seal passed all the required testing and was put into operation.

If you have a high-temperature or high-pressure seal need and are looking for a solution that will deliver performance 24/7/365, the expert team at Marco Rubber & Plastics is ready to help. For more than 40 years, we’ve been helping companies in multiple markets around the world seal the success of their applications, and we’re ready to do the same for you.

Connect with us today to speak with an application engineer.