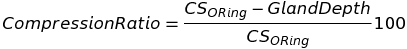

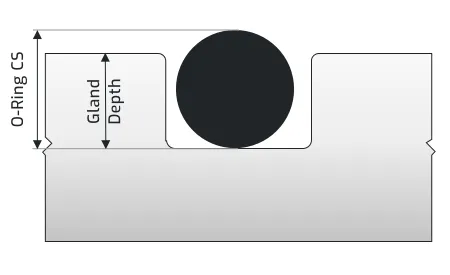

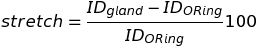

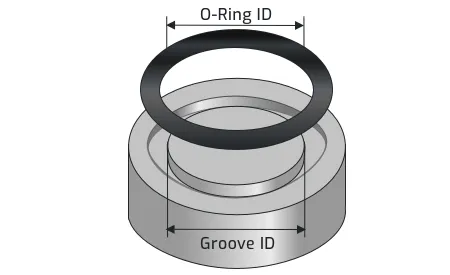

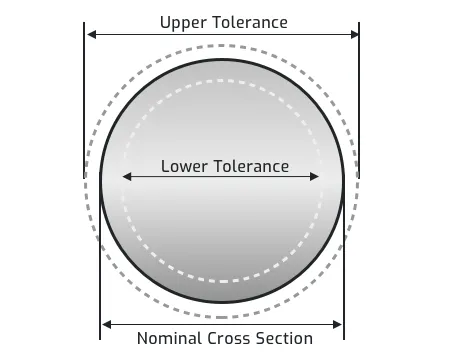

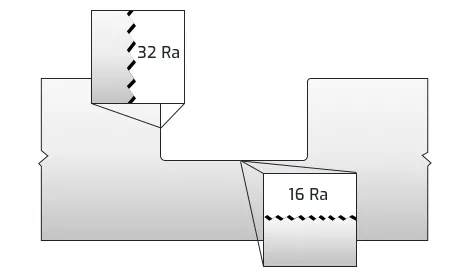

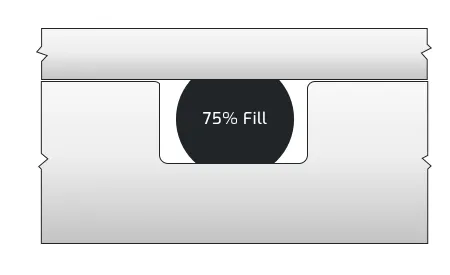

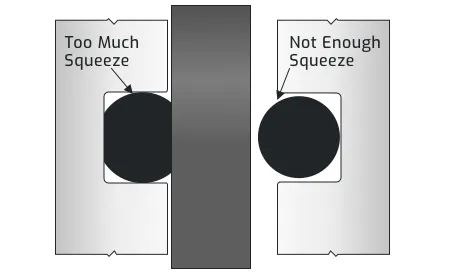

O-ring groove design is an important aspect of creating effective and reliable seals. It involves careful consideration of gland depth, surface finish, clearance, compression and more. Proper groove design provides optimal sealing performance, extends the lifespan of the O-ring, maintains pressure retention, reduces maintenance costs, and enhances overall application suitability. The wrong size groove makes even the best o-ring underperform.

Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design considerations to engineer on o-ring gland to optimize specific application performance.

Key Elements of O-Ring Groove Design

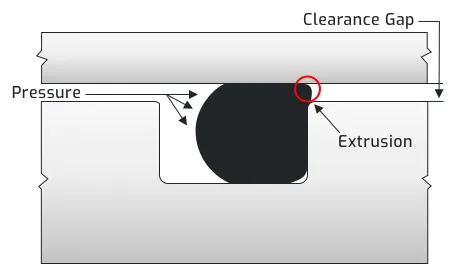

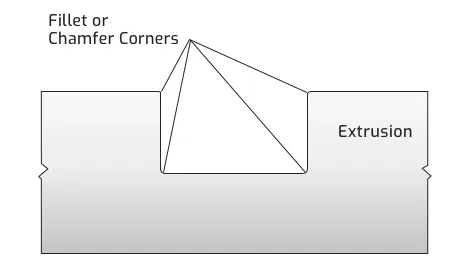

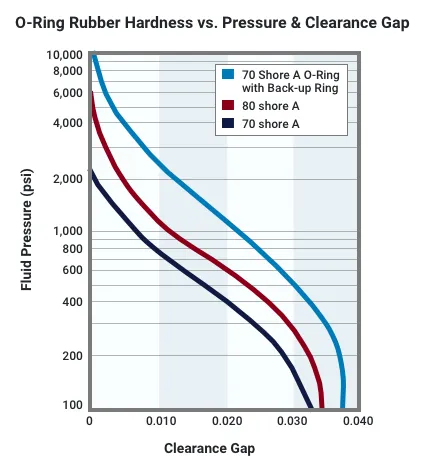

High Pressure Extrusion

Most o-rings are designed to operate at pressures up to 1,500 psi. At higher pressures, the material must have enough strength to resist extruding into the clearance gap. The chart shows the recommended combined limits of clearance, gap, material hardness and system pressure differential. To avoid extrusion at high temperature, reduce the extrusion gap, increase the seal material hardness or add a back-up ring to the o-ring but will require a wider gland.

Pressure Cycling

Cycling pressure can cause the o-ring to move back and forth within the gland. This motion can damage seals with low abrasion resistant materials. A higher durometer or an abrasion resistant material is recommended for these applications.

Choose Marco Rubber & Plastics

For more than 40 years, Marco Rubber and Plastics has been offering custom and standard o-rings and other sealing solutions for multiple industries. With millions of products produced and shipped annually, we are the trusted experts your organization needs to seal the success of your application.

Have Questions About Your Specific Application?

Connect With an Expert

- Expert product, application and design assistance

- Trusted by 14,000+ customers

- Fast response (usually within hours)