.webp)

- Sanitary Gaskets are available for the Food, Beverage, Dairy & Pharmaceutical processing industries.

- Sanitary Gaskets are available in Buna-N, Viton, EPDM, Silicone and PTFE. The materials are FDA compliant and some are USP Class VI certified.

- Gaskets are available in a wide variety of configurations.

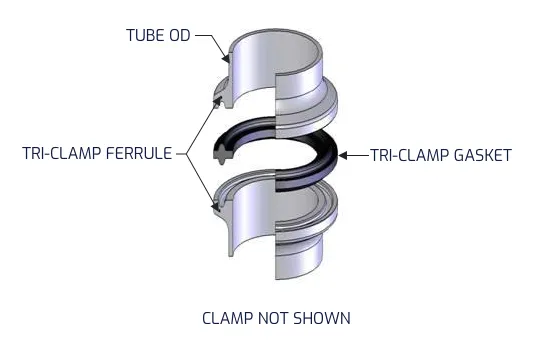

Tri-Clamp Sanitary Gasket - Sanitary Seals

Common Materials Available Standard or Metal or X-Ray Detectable

- NBR, Buna-N

- EPDM (Chloramine Resistant CPD Available)

- PTFE

- FKM, Viton®

- Aflas®

- FFKM, Kalrez® Type

Comh5liance Standards Available:

- FDA Compliant

- USDA 3-A Compliant

- USP Class VI Medical Grade

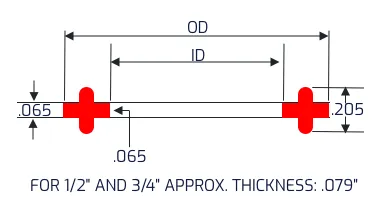

Approximate Dimensions of Standard Tri-Clamp Style Gaskets

| Dimensions | ID | OD |

|---|---|---|

| 1/2" | 3/8" | 1" |

| 3/4" | 5/8" | 1" |

| 1" | 7/8" | 2" |

| 1 1/2" | 1 3/8" | 2" |

| 2" | 1 7/8" | 2 1/2" |

| 2 1/2" | 2 3/8" | 3" |

| 3" | 2 7/8" | 3 1/2" |

| 4" | 3 7/8" | 4 1/2" |

| 5" | 4 3/4" | 5 1/2" |

| 6" | 5 3/4" | 6 1/2" |

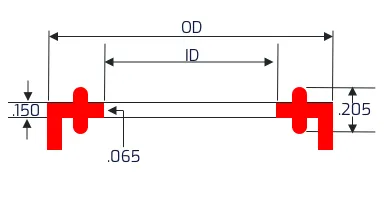

Approximate Dimensions of Standard Flanged Tri-Clamp Style Gaskets

| Dimensions | ID | OD |

|---|---|---|

| 1" | 7/8" | 2" |

| 1 1/2" | 1 3/8" | 2" |

| 2" | 1 7/8" | 2 1/2" |

| 2 1/2" | 2 3/8" | 3" |

| 3" | 2 7/8" | 3 1/2" |

| 4" | 3 7/8" | 4 1/2" |

| 5" | 4 3/4" | 5 1/2" |

| 6" | 5 3/4" | 6 1/2" |

| 8" | 7 3/4" | 8 1/2" |

| 10" | 9 11/16" | 10 1/2" |

| 12" | 11 11/16" | 12 1/2" |

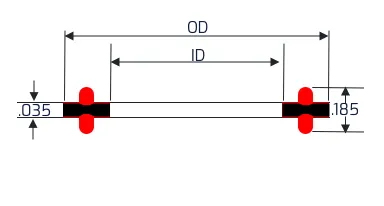

Approximate Dimensions of Teflon Envelope Tri-Clamp Style Gaskets

| Dimensions | ID | OD |

|---|---|---|

| 1/2" | 3/8" | 7/8" |

| 3/4" | 5/8" | 7/8" |

| 1" | 7/8" | 2" |

| 1 1/2" | 1 3/8" | 2" |

| 2" | 1 7/8" | 2 1/2" |

| 2 1/2" | 2 3/8" | 3" |

| 3" | 2 7/8" | 3 1/2" |

| 4" | 3 7/8" | 4 1/2" |

| 5" | 4 3/4" | 5 1/2" |

| 6" | 5 3/4" | 6 1/2" |

| 8" | 7 3/4" | 8 1/2" |

| 10" | 9 3/4" | 10 1/2" |

| 12" | 11 3/4" | 12 1/2" |

Popular Compounds

Compound # | Datasheet | Material | Hardness (Shore A) | Color | Low Temp °F (°C) | High Temp °F (°C) | FDA | USP Class VI | NSF61 | USDA 3A | Metal Detectable | Features |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

E1000 | EPDM | 70 | Black | -65 (-54) | 300 (149) | Peroxide cured EPDM, Different Durometer, KTW, WRAS standards available | ||||||

E1074 | EPDM | 70 | White | -65 (-54) | 300 (149) | Wide range of compliance | ||||||

E1080 | EPDM | 70 | Black | -40 (-40) | 250 (121) | Wide range of compliance | ||||||

E1097 | EPDM | 70 | Black | -65 (-54) | 300 (149) | Formulated for Chloramine Resistance. Can be manufactured in custom shapes with minimal setup charge | ||||||

B1002 | NBR | 70 | Black | -30 (-34) | 250 (121) | Available in many durometers and colors | ||||||

B1039 | NBR | 70 | White | -30 (-34) | 250 (121) | Available in many durometers and colors | ||||||

B1058 | NBR | 70 | Black | -30 (-34) | 250 (121) | KTW, WRAS and other standards available | ||||||

B1105 | NBR | 70 | Black | -30 (-34) | 250 (121) | Metal detectable for contamination detection sensors(additional colors available) | ||||||

S1000 | VQM | 70 | Orange | -75 (-59) | 400 (204) | Available in many durometers and colors | ||||||

S1020 | VQM | 70 | Clear Translucent | -75 (-59) | 400 (204) | Clear Translucent, available in many durometer and color choices | ||||||

S1037 | VQM | 70 | Clear Translucent | -75 (-59) | 400 (204) | Clean room manufactured, platinum cured (specific base materials and cleanroom packaging options available) | ||||||

S1083 | VQM | 70 | Clear Translucent | -65 (-54) | 400 (204) | Commercial manufactured, platinum cured (cleanroom manufacturing and packaging options available) | ||||||

S1146 | VQM | 70 | White | -75 (-59) | 480 (249) | Cleanroom manufactured, Lower cost than clear | ||||||

V1039 | FKM | 75 | White | -15 (-26) | 437 (225) | Cleanroom manufacturing and packaging options available | ||||||

V1118 | FKM | 70 | White | -15 (-26) | 437 (225) | Steam Resistant Terpolymer, Also available in black | ||||||

V1148 | FKM | 70 | Black | -15 (-26) | 392 (200) | Metal detectable for contamination detection(additional colors available) | ||||||

Z1204 | FKM | 75 | Black | 20 (-7) | 450 (232) | FDA compliant, higher temperature resistance, wide chemical compatibility. Compare to Kalrez® 6230, Kalrez® LS222 | ||||||

Z1409 | FKM | 75 | Black | -4 (-20) | 500 (260) | Low cost performance value, nearly universal chemical compatibility, acid, amines, solvents, compression set resistance, FDA compliant and USP Class VI medical grade. Compare to Kalrez® 6230, Kalrez® LS222 | ||||||

Z1318 | FKM | 75 | White | 5 (-15) | 500 (260) | USP Class VI and FDA compliant white FFKM with wide range compatibility. Compare to Kalrez® 6221, Kalrez® LS205, Chemraz® 625 | ||||||

Z1305 | FKM | 80 | White | 5 (-15) | 590 (310) | USP Class VI and FDA compliant white FFKM with wide range compatibility. Compare to Kalrez® 6221, Kalrez® LS205, Chemraz® 625 |

The information on this page is to the best of our knowledge accurate and reliable. However, Marco Rubber makes no warranty, expressed or implied, that parts manufactured from this material will perform satisfactorily in the customer's application. It's the customer's responsibility to evaluate parts prior to use.

The temperature ranges presented on this page are approximations for dry air service only and should not be used to determine design specifications or end-use temperature limits. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. The most practical way of determining an end-use temperature range is testing in the actual application conditions. Consult a Marco Engineer for more details.

*FDA compliance per 21 CFR 177.2600 parts A-D, E&F approved compounds available upon request. **USP <87> and USP <88> approved compounds available upon request.

The temperature ranges presented above are approximations for dry air service only and should not be used to determine design specifications or end-use temperature limits. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. The most practical way of determining an end-use temperature range is testing in the actual application conditions. Consult a Marco Engineer for more details.

Have Questions About Your Specific Application?

Connect With an Expert

- Expert product, application and design assistance

- Trusted by 14,000+ customers

- Fast response (usually within hours)