Teflon® Encapsulated O-Ring Material and Size Guide

High Performance Products for Demanding Environments

Teflon® encapsulated o-rings and spring energized seals offer many performance benefits in demanding environments. FEP and PFA Teflon® fluoropolymer shell delivers excellent chemical resistance with the energizing resiliency of a rubber elastomer core combines the best of both materials for o-rings with extreme chemical and temperature resistance.

Teflon® encapsulated o-rings are more stiff than solid rubber so can require special groove design considerations for optimal performance. Contact our responsive experts for engineering support.

Marco Rubber has many commonly used sizes of Teflon® encapsulated o-rings in-stock, and custom sizes are made within a few weeks without tooling fees.

| Seal Type | Compound # | Low Temp °F (°C) | High Temp °F (°C) | Pressure Range | Dynamic Application | Slow Dynamic Application | Excellent Chemical Compatibility | Static Application | Features |

|---|---|---|---|---|---|---|---|---|---|

| FEP Encapsulated Silicone Core | T1002 | -76 (-60) | 400 (204) | Up to 1500 psi | Most Readily Available | ||||

| FEP Encapsulated Hollow Silicone Core | T1003 | -76 (-60) | 400 (204) | Up to 500 psi | Less Force Required to Compress | ||||

| FEP Encapsulated FKM (Viton®) Core | T1001 | -15 (-26) | 400 (204) | Up to 1500 psi | Greater Chemical Resistance and Compression Set Resistance | ||||

| FEP Encapsulated Steel Spring Core | T1021 | -420 (-251) | 400 (204) | Up to 3000 psi Vents | Cryogenic Sealing Applications | ||||

| Steel Spring Energized PTFE (Teflon® ) Seal | -420 (-251) | 600 (316) | Up to 60,000psi Design | Extreme Temperature, High Pressure, and Chemical Resistance. Dynamic Application Performance | |||||

| Solid FFKM Markez® | FFKM | -50 (-46) | 620 (327) | Up to 25,000 psi with back-up ring | Improved Sealing Performance Longer Seal Life |

The information on this page is to the best of our knowledge accurate and reliable. However, Marco Rubber makes no warranty, expressed or implied, that parts manufactured from this material will perform satisfactorily in the customer's application. It's the customer's responsibility to evaluate parts prior to use.

The temperature ranges presented on this page are approximations for dry air service only and should not be used to determine design specifications or end-use temperature limits. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. The most practical way of determining an end-use temperature range is testing in the actual application conditions. Consult a Marco Engineer for more details.

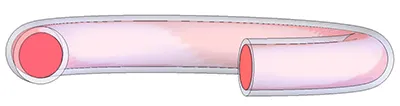

FEP Encapsulated Silicone O-Rings

O-Ring with a FEP or PFA (Teflon®) outer layer encapsulating a Silicone core. The Teflon® shell offers excellent chemical and temperature resistance while the Silicone core provides the resiliency needed to provide effective sealing. Readily available in common USA and metric cross-sections and nearly unlimited diameters. CPD# T1002 is FEP encapsulated Solid Silicone with improved chemical resistance up to +400°F. CPD# T1022 is PFA encapsulated Solid Silicone up to +500°F.

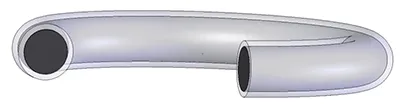

FEP Encapsulated Silicone Hollow Core

O-Ring with a FEP (Teflon®) outer layer encapsulating a Hollow Silicone core. The Teflon® shell offers excellent chemical and temperature resistance while the Hollow Silicone core provides the resiliency needed to provide effective sealing. The hollow core requires less force to compress the seal resulting in easier installation and improved sealing performance in some applications. Readily available in common USA and metric cross-sections and nearly unlimited diameters. CPD# T1003 is FEP encapsulated Hollow Silicone with up to +400°F.

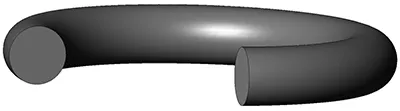

FEP Encapsulated FKM (Viton ®) Core

O-Ring with a FEP (Teflon®) outer layer encapsulating a Solid FKM (Viton®) core. The Teflon® shell offers excellent chemical and temperature resistance while the FKM core provides the resiliency needed to provide effective sealing. The FKM core provides increased chemicals and compression set resistance resulting in longer lasting sealing in some applications. Readily available in common USA and metric cross-sections and nearly unlimited diameters. CPD# T1001 is FEP encapsulated Solid FKM with improved chemical resistance up to +400°F.

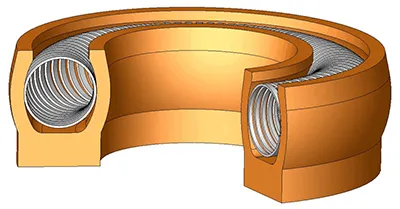

FEP Encapsulated Steel Spring Core

O-Ring with a FEP (Teflon®) outer layer encapsulating Stainless Steel Spring. The Teflon® shell offers excellent chemical and temperature resistance while the Steel Spring core provides the resiliency needed to provide effective Cryogenic Seal performance down -420°F. Readily available in USA and metric cross-sections and nearly unlimited diameters. CPD# T1021 is FEP encapsulated Steel Spring with Cryogenic Sealing down to -420°F and up to +400°F. PFA encapsulated steel spring up to +500°F.

Steel Spring Energized PTFE (Teflon ®) Seals

PTFE (Teflon®) U-Cup style Lip Seal energized by a stainless steel spring. Spring Energized Teflon Seals provide the best chemical resistance, widest temperature and pressure performance ranges of any plastic or elastomeric seal. Spring Energized Teflon Seals can perform in Cryogenic Sealing temperatures of nearly absolute zero -420°F to 600°F. Pressures up to 3,000 psi and custom designs allow up to 60,000 psi. A wide range of high performance plastics are available for specific application performance. Designed for radial, face or custom seal configurations, as well as rotary, reciprocating and oscillatory motions depending on design. Low friction and long service life in demanding application. Wide range of spring energizing configurations based on applications. Seals are available in Rod and Piston Inside and Outside Pressure and unidirectional sealing configurations. Great performance in compressed gas waterless fracking seals, LPG and Liquid Nitrogen seals. Alternative to MSE® Seals, Bal Seals, Variseal®, FlexiSeal®.

Solid FFKM Markez®

O-Rings and Custom Molded FFKM MARKEZ® KALREZ® Seals provide the ultimate chemical, temperature and sealing performance in demanding applications that are worth investing in high performance high cost seals. Dozens of specialized compounds are available to maximize specific application performance temperatures to -50°F and +620°F.

Common Applications

- Valve Stems

- Flanges

- Pumps

- Swivels

- Turbo Pumps

- Joints

- Turbo Expanders

- Cryogenic seals

- Waterless fracking

Encapsulated O-Ring Common Cross Sections and Diameters

| O-Ring Cross-Section (inches) | O-Ring Cross-Section (mm) | Recommended Compression (inches) | Minimum ID | Maximum ID |

|---|---|---|---|---|

| 0.070 +/- .005 | 1.78 | 0.017 | 0.5 | 10 |

| 0.075 +/- .005 | 1.91 | 0.018 | 0.5 | 10 |

| 0.094 +/- .005 | 2.4 | 0.022 | 0.6 | 15 |

| 0.103 +/- .005 | 2.62 | 0.024 | 0.6 | Unlimited |

| 0.110 +/- .005 | 2.79 | 0.025 | 0.6 | Unlimited |

| 0.118 +/- .005 | 3 | 0.025 | 0.75 | Unlimited |

| 0.125 +/- .006 | 3.18 | 0.025 | 0.75 | Unlimited |

| 0.139 +/- .006 | 3.53 | 0.025 | 0.75 | Unlimited |