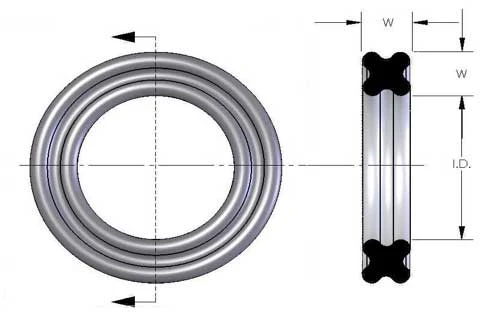

X-Rings and Quad-Ring® Seals

Explore Quad-Ring® and X-Ring Seals for Reduced Friction Applications

X-Rings, also known as Quad-Ring® Seals, can be used in a wide variety of static and dynamic sealing applications. In reciprocating applications, the X-Ring four-lobed design prevents spiral failure and in rotary applications, it prevents the seal from bunching and failing. We supply both Quad-Ring® branded seals manufactured by Minnesota Rubber and Plastics, Quadion LLC as well as similar seals described in various ways like X-Rings and Q-Rings.

The four-lobed design provides two sealing surfaces in comparison to a standard O-ring. The double-seal action requires less force to maintain an effective seal. This reduction in force means less friction and improved seal life.

X-Ring parting lines are between the lobes, away from the sealing surface, thus eliminating the problems of leakage often resulting from a parting line's irregular surface as found on an O-Ring. The unique design of the X-Ring allows it to be used in narrower grooves and also in standard width O-ring grooves.

Features

- Recommended for low speed reciprocating or oscillatory motion if O-Rings twist.

- Provides lower friction than O-Rings and Square Rings.

- X-Rings are interchangeable with O-Ring sizes and glands design.

- Available in the same size standards and custom sizes as O-Rings.

- Readily available in USA AS568 standard sized NBR Buna-N and FKM.

- Not recommended for pressures >500 psi.

- X-Rings may not be available in all compounds.

- Custom size X-Rings can require a tooling cost in some compounds.