Marco Rubber Ohmerics® EMI RFI Shielding Fabric over Foam Gasket materials are cost effective alternatives to Chomerics® Soft-Shield® consisting of electrically conductive coated polyester woven over a highly compressible and resilient polyurethane foam used to form physical sealing barriers as well as providing EMI and RFI shielding electronic equipment from unwanted emissions or noise.

- Our most common material configurations are UL Certified flame retardant, RoHS compliant and Halogen free.

- Abrasion resistant metalized fabric shows virtually no degradation in Shielding performance after 800,000 cycles.

- High performance urethane foam core provides low compression set ensuring long term sealing performance.

- Available in a wide range of shapes and profiles with conductive or non-conductive pressure sensitive adhesive.

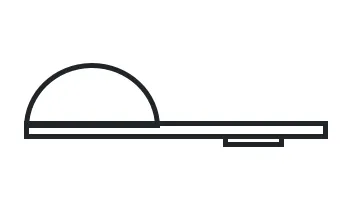

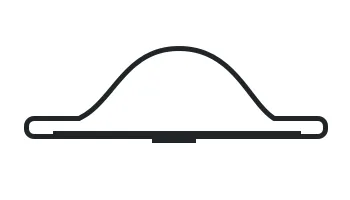

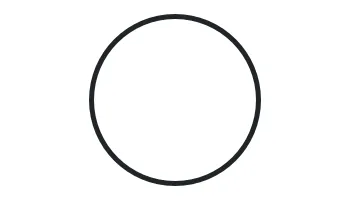

Foam Gasket Shapes

Foam gaskets are available in a variety of different shapes. The specific shape of the foam gasket can provide better functionality in particular applications.

Products can be produced in almost any configuration imaginable, from cut gaskets to custom shapes often without tooling fees. Specific properties and test data are available. For assistance in selecting the material that provides the best combination of performance and price for your specific application, please contact a shielding application engineer.

Ohmerics® Fabric Over Foam Material Comparison Table

Ohmerics® Compound | Conductive Coating | Weave Style | Surface Resistance (OHMS/SQIN) | Shielding Effective (DB) | Compression Set | Operating Temp Range °C | Typical Use |

|---|---|---|---|---|---|---|---|

FOFNCT | Nickel/Copper | Teffeta | .02 - .05 | 60 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFNCR | Nickel/Copper | Ripstop | .02 - .05 | 60 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFST | Silver | Teffeta | .02 - .05 | 60 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFSR | Silver | Ripstop | .02 - .05 | 60 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFGT | Gold | Teffeta | .01 - .04 | 70 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFGR | Gold | Ripstop | .01 - .04 | 70 - 100 | < 15% | -40 to +70 | Commercial & Military |

FOFNCAT | Nickel/Copper Anti Corrosion | Teffeta | .045 - .10 | 60 - 90 | < 15% | -40 to +70 | Commercial & Military |

FOFNCAR | Nickel/Copper Anti Corrosion | Ripstop | .045 - .10 | 60 - 90 | < 15% | -40 to +70 | Commercial & Military |

The information on this page is to the best of our knowledge accurate and reliable. However, Marco Rubber makes no warranty, expressed or implied, that parts manufactured from this material will perform satisfactorily in the customer's application. It's the customer's responsibility to evaluate parts prior to use.

The temperature ranges presented on this page are approximations for dry air service only and should not be used to determine design specifications or end-use temperature limits. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. The most practical way of determining an end-use temperature range is testing in the actual application conditions. Consult a Marco Engineer for more details.