Your seal is your first line of defense between you and dangerous spills, expensive repairs, and frustrating downtime. In applications that experience extreme temperatures and chemical exposure, finding a sealing solution can feel nearly impossible. That is where flexible graphite comes in.

This unique material is produced by immersing natural flake graphite into a chromic acid bath, followed by concentrated sulfuric or nucleic acid. This forces the crystal lattice planes apart and expands the graphite.

All in all, this process creates a versatile material that offers sealing solutions unlike any other material. Known for its exceptional thermal conductivity, heat resistance, and chemical resistance, flexible graphite is often used in:

- Fugitive emissions applications

- Specialty sets, like helium

- Nuclear seals

- Power generation

- Thermal pads

- Oil and gas and chemical plants

- Oven seals

- Semiconductors

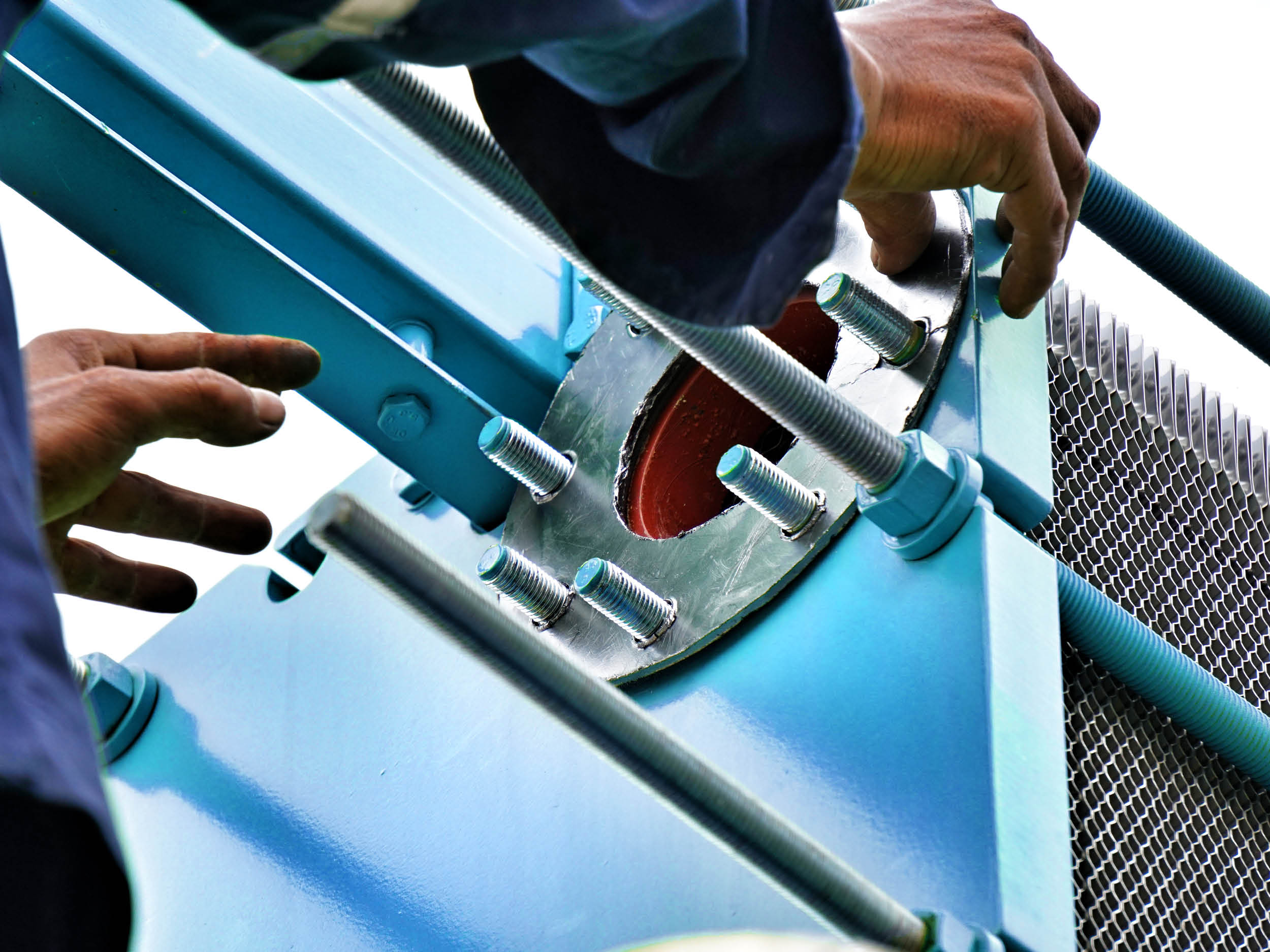

- Pipe flange gaskets

- Valve stem seals

- Aerospace engine and propulsion seals

- Exhaust seals

All these applications, along with the myriad of other applications where flexible graphite is used, experience circumstances that make it impossible to use other sealing materials. Flexible graphite’s benefits make it the ideal choice for these applications.

Benefits of Flexible Graphite

Flexible graphite is a mainstay of several industries, including:

- Oil & Gas

- Pumps

- Power Generation

- Aerospace

- Pulp & Paper

- Steel

- Automotive

With the ability to handle a pH range of 0 to 14, flexible graphite offers nearly unparalleled chemical resistance. But what really sets flexible graphite apart is its impressive temperature range. In an oxygen environment, flexible graphite has a temperature range of -400°F to 850°F. In steam applications, that range increases to -400°F to 1,200°F. Outside of the ozone, where oxygen is not present, flexible graphite’s temperature range extends even further to an incredible -400°F to 5,400°F.

Forms of Flexible Graphite

Like any good sealing solution, flexible graphite comes in a range of forms to fit a number of applications. There are a few common forms which provide a wide range of options.

Sheet Gasket Materials

Flexible graphite is most commonly available as homogenous, foil inserted, or tang inserted.

Homogenous flexible graphite does not have an insert, which equates directly to the thickness of the material. If the material is thicker, its need for an insert to improve handleability is reduced. This sheet gasket is easier to cut than its counterparts that use a metal sheet, and it does not require adhesives for thinner variations. If a thicker sheet is required, it is often laminated up with adhesive.

Foil inserted flexible graphite has a .002” stainless steel insert. This insert primarily improves handleability and blow out prevention. As flexible graphite is fragile with very little tensile strength, adding this thin layer of metal at its core greatly improves handling.

For applications where off-gassing is a factor, there is also a tang insert option, which uses a .004” stainless steel insert. The tang material mechanically bonds to the flexible graphite which limits the amount of adhesive required.

Cut Gaskets

Another common form of flexible graphite is cut gaskets. These can be cut with a knife edge or water jet CNC as well as by hand, specific types of lasers, or a clicker press. Using Autocad, flexible graphite can be made into a wide range of cut gaskets and cut simply for your needs, allowing for high levels of customization. Other benefits include:

- Optimal Seals

- Reduced Waste

- Complex Geometry

- Material Selection

- Single-Piece Design

- High-Performance Materials

- Improved Efficiency

- Cost-Effective for Custom Shapes

- Reliable Performance

Die-Formed Rings

Flexible graphite die-formed rings are made from stripped flexible graphite sheet material, which is rolled into 100 foot “ribbon pack rolls.” This ribbon pack is wrapped around a mandrel and placed into a die, thus creating the die-formed rings.

Depending on your needs, flexible graphite allows you to add wire for added pressure resistance or metal end caps to improve extrusion resistance. These rings can be square, rectangular, or cup and cone shaped. They are frequently used for sealing valves, pumps, and other equipment.

Braided Packing

Braided flexible graphite has come in handy for many maintenance departments. This form of flexible graphite can be used in a wide range of applications which require a wide temperature range, chemical compatibility, and pressure resistance.

Braided flexible graphite can be made into rings, as well. It provides reinforcement that other die-formed rings might not be able to provide and makes it the ideal solution for:

- Packing and Sealing

- Gaskets

- Heat Exchangers

- High-Temperature Insulation

- Cryogenic Applications

- Chemical Processing

- Electrical Applications

- Automotive and Transportation

Finding a Flexible Graphite Supplier

Flexible graphite provides an optimal solution for many of the harshest sealing applications, and now it is easier than ever to get your hands on. Here at Marco Rubber, we have added flexible graphite to our repertoire of sealing solutions.

When you work with us, you get the Marco experience. We are dedicated to constant innovation to meet our customers’ ever changing needs. But our dedication does not stop there. We provide our customers with solutions that truly work and are customized to their exact application whenever necessary. Our customers’ success is our success.

This is evidenced by our ISO 9001:2015 certification, demonstrating our dedication to continuous improvement, innovative and adaptive leadership, evidence-based decision making, and top-of-the-line quality management. When you work with Marco Rubber, you don’t just get a sealing product – you get a quality solution that has been rigorously tested.

This is true of our line of flexible graphite, as well. We provide only high-quality flexible graphite designed to live up to your toughest sealing applications.

So is flexible graphite the solution you have been looking for? Contact us today to find out.