High-Pressure Reliability for Oil and Gas Seals

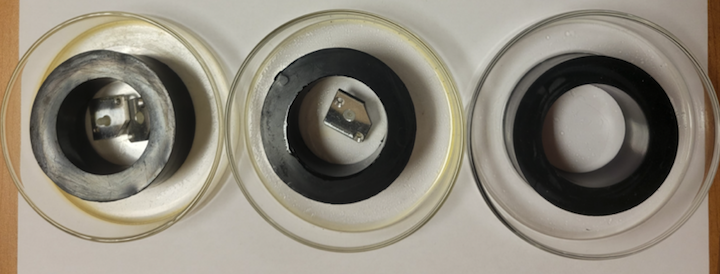

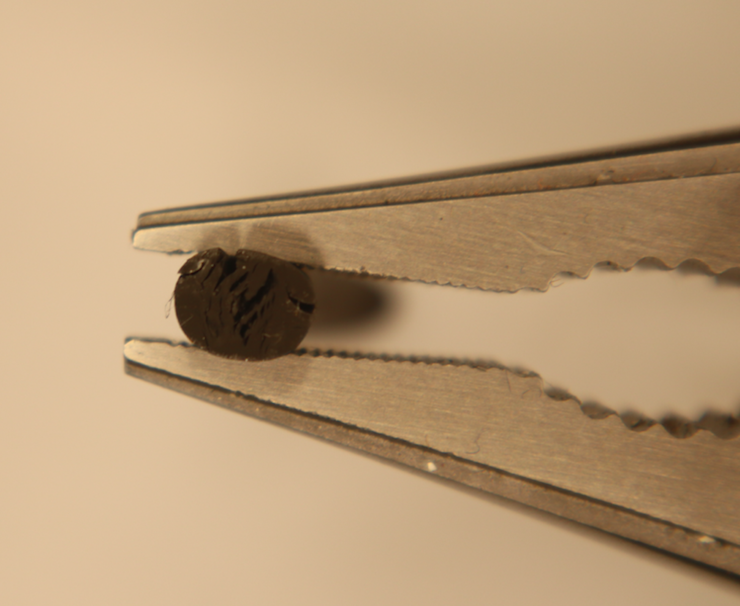

The oil and gas industry constantly pushes seal materials to their limits with high-pressure gas systems. Every cycle adds mechanical and thermal stress. Rapid decompression can pull trapped gas through the seal body, forming cracks that grow until the part fails. Joint seams and poor vulcanization only accelerate the problem. The Challenge A leading manufacturer […]