The Challenge: Maintaining Performance Under High Pressure

Most seal companies will recommend high durometer o-rings for high-pressure applications, often to the tune of 90 and 95 Shore A hardness. When those pressures exceed 3,000 psi, it’s also recommended to use o-rings with a back-up ring to prevent cracks that cause leaks and other failure issues.

The reasoning behind this is that at high pressures, the higher-durometer o-rings will resist extrusion better than a lower durometer o-ring. In fact, back-up rings also help to improve the pressure and temperature resistance of the o-ring it’s supporting. They are flexible, can be designed in a variety of shapes and configurations, and can be used on either side of the o-ring if the pressure is bidirectional.

The Solution: A Back-Up Ring Tailored to the Application

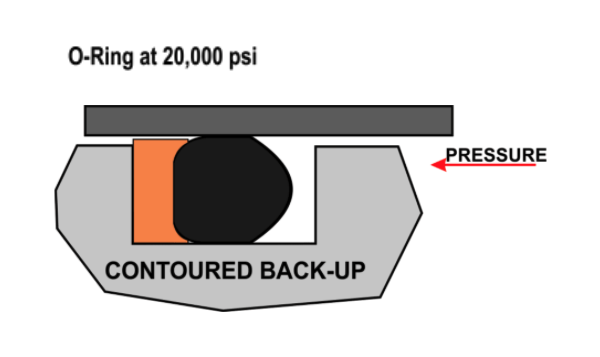

At Marco Rubber & Plastics, we evaluate the full application to offer a complete seal solution. There are some cases where the back-up ring configuration plays a very important function. In the illustration below, a high durometer o-ring with a standard configuration back-up ring was working fine up to 10,000 psi, but at higher pressure, the seal started to leak profusely.

It was discovered that once the pressure went higher than 10,000 psi, the o-ring material could no longer stretch and deform to fill the gap behind the o-ring, resulting in cracks.

The Result: Contouring to Support the Primary O-Ring

By making a contoured back-up ring, the gap behind the o-ring was eliminated and the o-ring did not suffer any damage in pressures up to 20,000 psi. This ensured the performance of the application in some of the most demanding, high-pressure scenarios.

If you have a high-pressure application or even an application that may occasionally be subjected to higher pressures, it’s critical to have the right seal for the job. Standard and cheap seals are costly in more ways than one. That’s why the expert team at Marco Rubber & Plastics will work closely with you to understand your specific application and develop a solution that achieves the level of performance needed.

Connect with us today to speak with an application engineer.