5 Things Semiconductor Engineers Should Do to Perfect Their Seals

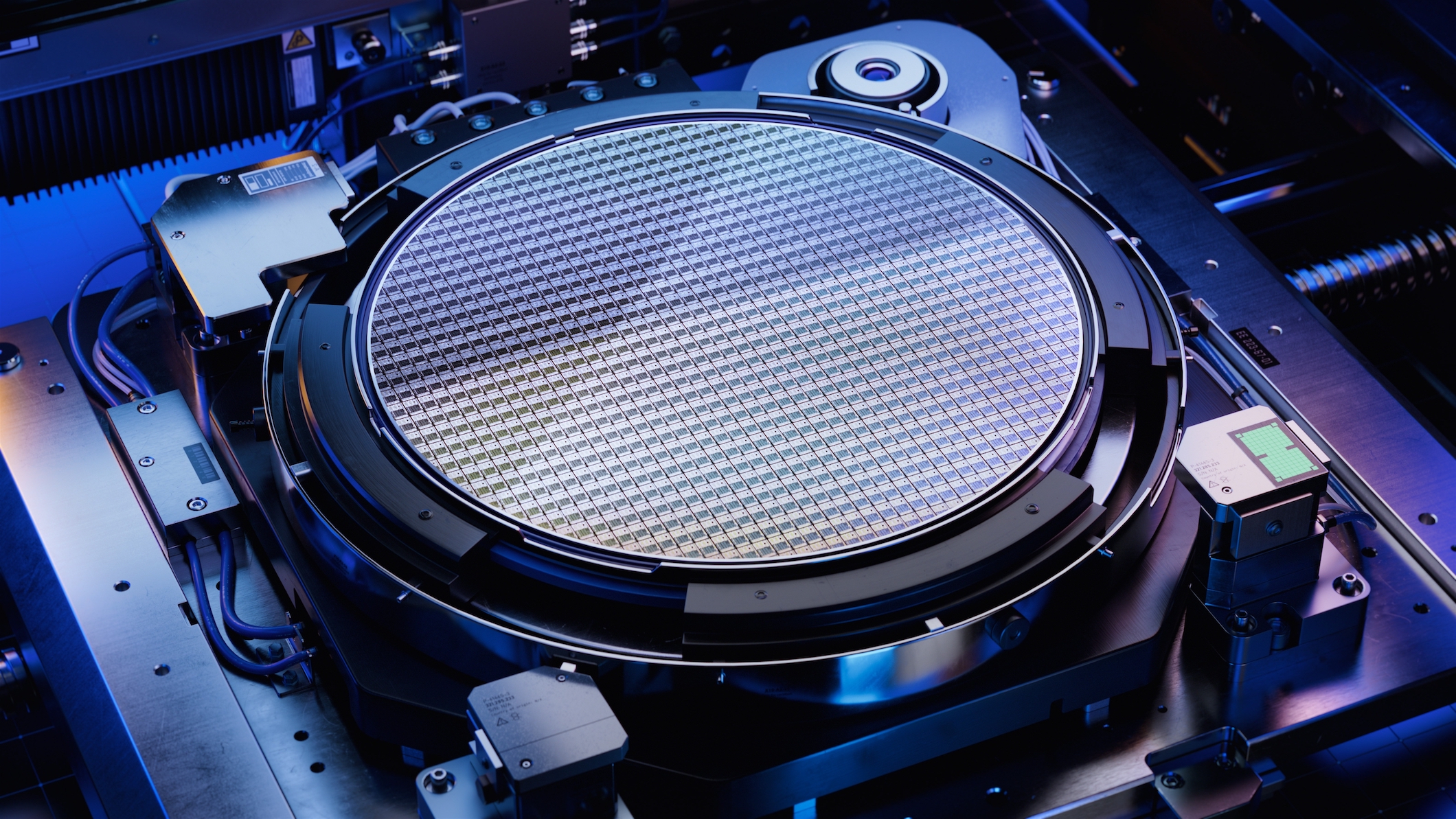

The world as we know it would not be possible without computers – and those technologies would be impossible without semiconductors. Yet their production comes with unique challenges as the wafers become increasingly smaller – and contamination becomes an even larger risk to their integrity and functionality.

One factor of semiconductor manufacturing that is often overlooked is the seals throughout the process. Your seals will either make or break your design – making your life easier or extraordinarily difficult. Every application is unique and needs a seal that is going to live up to the job, so that you can focus on the bigger picture without worrying about the intricacies. If you are looking to improve your seals in semiconductor manufacturing, we have five recommendations that we, as sealing experts, believe are imperative for robust sealing.

1. Use O-Rings Made in a Cleanroom

First things first: because semiconductors are so sensitive to contamination, all components involved in their production should be free of both particle traps and particles. This includes sealing components such as o-rings.

Cleanrooms provide protection from particles during the production, cleaning, and packaging processes. Moreover, cleaning components with deionized water (DI water) in a cleanroom removes additional contaminants.

Where water is concerned, anything other than the hydrogen (H+) and hydroxyl (OH-) ions are considered impure. The process of deionization removes any other charged ions so the water can reach its purest level. Using this water to bathe a product that was manufactured in a cleanroom before packaging it helps remove any particles generated during the production process, resulting in an ultra pure product.

2. Look for O-Rings With High Chemical Resistivity

Numerous chemicals are used in the production of semiconductors. They can improve the efficiency and cost-effectiveness of many electronic manufacturing processes. But they can also pose material compatibility problems for the components of your design, especially your seals.

Many forms of rubber can be easily corroded by these very harsh chemicals, which can lead to failure over time. Thus, when designing your seals, you will want to use specific formulations, such as FFKM, designed to have high chemical resistivity.

3. Consider Custom Sizing

Your design is unique – and every seal needed in your design should be carefully considered. There is no true single “one size fits all” approach in seal design, especially in complex applications. While some seals might be straightforward, others will require a special approach. Thus, it is important to consider a full range of options for seal design and selection.

4. Find Affordable Products That Don’t Compromise

Your seal is a critical component of your design. Due to its importance and the sensitive nature of semiconductor manufacturing, high-quality o-rings and other sealing solutions that meet the requirements of the industry can get expensive quickly. After all, you need high levels of stability, resistance, temperature stability, long-term performance, and effectiveness.

But you can find these attributes without the high price tag. The key is knowing the exact requirements and finding a seal to match, looking beyond the big brands at times to find the right solution.

5. Talk to a Sealing Expert

When we say “know what you need and ask the right questions!” it only works if you, in fact, know what you need and ask the right questions.

When you are navigating complex applications, consulting with a sealing expert can drastically reduce the stress on you and significantly improve your seal for semiconductor manufacturing. The sealing expert is responsible for reviewing your specific needs and application and providing recommendations to ensure a robust solution. You have enough on your plate – and becoming an expert on seals does not need to be one of those things.

Where to Find Cleanroom Manufactured O-Rings

If you are looking to perfect your seals in semiconductor manufacturing, we have a final recommendation to make your life substantially easier: consider Markez Z1421, a high-quality, affordable FFKM compound designed for sterile use within the semiconductor industry.

Markez Z1421 is manufactured, cleaned with deionized water, and packaged in a cleanroom. It was built for use in harsh environments. With a high chemical resistivity, it is able to withstand the chemicals used in semiconductor manufacturing as well as withstanding the solvents used for cleaning. It is also formulated for the high temperatures in developing semiconductors.

Markez is a Marco Rubber product, which means it comes with all that Marco Rubber offers. We are dedicated to ensuring our customers have the best possible experience. That is why we offer unfettered access to our sealing experts, who will help you identify and customize a solution specifically for your needs. Moreover, we aim to make our products both affordable and readily available. Markez Z1421 is currently available with short lead times to ease your logistics challenges.

If you are looking to perfect your seal for semiconductor manufacturing, talk to our team today about what the affordable, highly durable, customizable, and readily available Markez Z1421 can do for you.