Semiconductor and solar panel production runs on tight schedules. A single delay in the supply chain can slow down lines, raise costs, and create risk for downstream processes. During the COVID-19 labor shortage, a semiconductor manufacturer was facing a challenge that threatened their output and created a risk of costly delays.

The manufacturer reached out to Marco Rubber & Plastics for help. They needed a partner who could move quickly and ensure a stable, reliable supply. Using modern equipment and a disciplined approach, Marco delivered the dependable output the customer needed.

The Challenge: Supply Chain Strain in Semiconductor Manufacturing

The customer was dealing with delays, uneven output, and mounting concerns about meeting demand. In a semiconductor operation, consistency and timing are everything. Uncertainty puts production at risk.

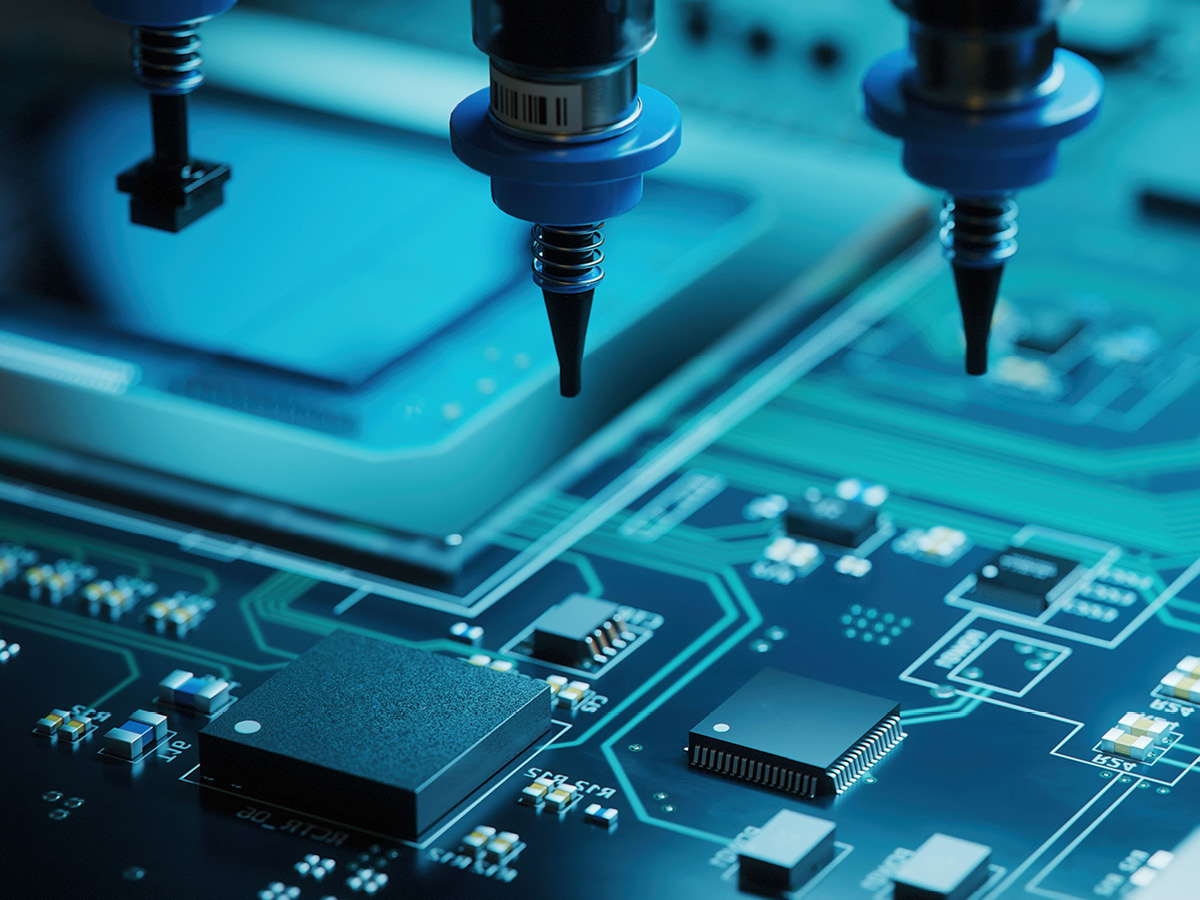

The component at the center of the problem was a metallic overmolded multi-cable lock. It required precise molding and consistent tolerances to ensure every part performed the same way. The customer needed a partner who could take on the challenge of engineering the part, scale quickly, and deliver with reliability.

The Solution: Modernizing and Scaling Production

The multi-cable lock required repeatable precision. Marco’s disciplined methods and modern equipment ensured those standards were met. Their background in semiconductor manufacturing meant the same methods used for high-purity seals and cleanroom sealing solutions could be applied here. That meant consistency and reliability, from the start. The customer’s standards were exceeded with Marco.

Production was streamlined. Safety improved, and throughput increased. With Marco’s support, supply was now reliable.

The Outcome: Reliability at Scale

The customer approved fifteen SKUs produced by Marco. Each part had the precision and reliability required for semiconductor use with its tight tolerances and consistent performance. Uncertainty was replaced with dependable supply.

Performance at this level did not go unnoticed. Marco was added to ABB’s worldwide supplier database. This recognition confirms our ability to deliver at scale. For the customer, this meant less downtime, fewer missed schedules, and confidence that critical parts would be ready when needed.

What began as an urgent need during uncertain times turned into a lasting partnership. Marco proved they could not only stabilize supply in the short term but also deliver long-term reliability in one of the world’s most demanding industries.

Takeaway

Semiconductor and solar manufacturers depend on precision, reliability, and steady supply. When those are at risk, production slows and costs rise.

Marco Rubber & Plastics delivers more than just seals. With our proven processes, modern equipment, and semiconductor experience, Marco stabilized a critical supply chain while building confidence for the long term.

Marco is the partner that keeps production moving when reliability is non-negotiable.

Speak with a Marco engineer today about your semiconductor components or supply chain challenges.