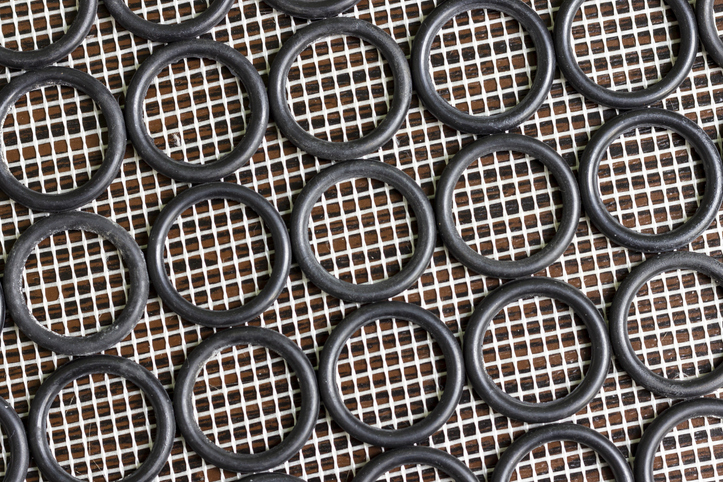

Consolidated Sealing Solutions for Manufacturing

How long is your supply chain? How many contacts do you manage? According to a recent study, only 6% of companies feel they have full visibility over their supply chain, but the same survey revealed that 57% of companies believe that managing their supply chain well gives them a competitive advantage. That is a glaring […]