Using Custom Rubber Diaphragms

Is a low-cost component costing you more than it’s worth?

In many pressure-sensitive assemblies, the rubber diaphragm is overlooked until performance drops. Systems begin experiencing inconsistent pressure, premature wear, and unexpected chemical degradation. These are signs that a standard diaphragm isn’t cutting it anymore.

Custom rubber diaphragms solve problems that off-the-shelf parts can’t. They’re designed for repeatable performance under specific pressures, temperatures, and chemical exposures. Behind the scenes, they’re working hard to move fluids and gases in critical systems worldwide.

How Rubber Diaphragm Seals Work

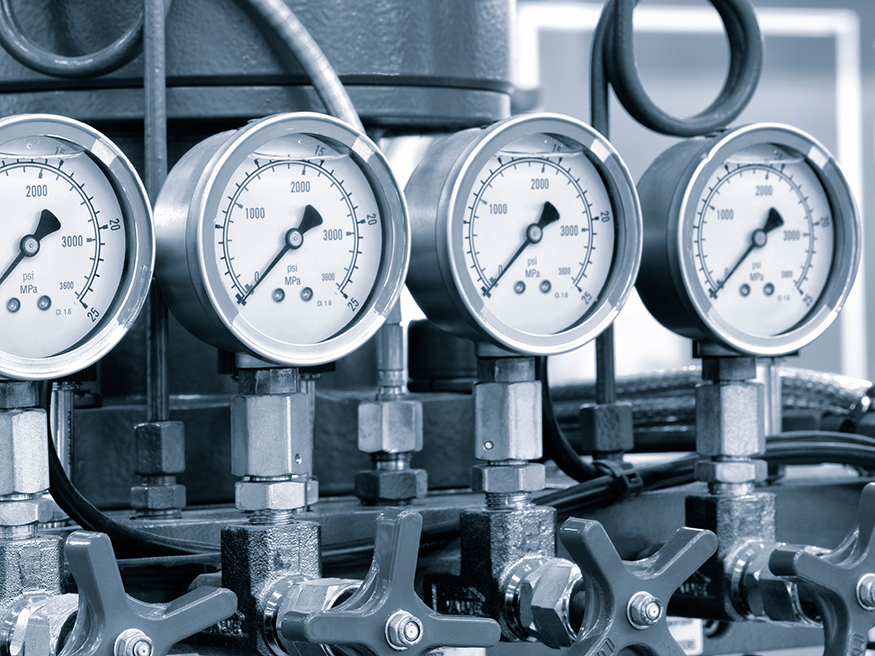

A diaphragm seal exists within a connection to create a flexible barrier that separates the instrument from the process fluid. This is critical in systems with chemicals, pressure spikes, or particulates that could damage valves, gauges, or sensors. The diaphragm transmits pressure without letting the process fluid reach the instrument. It protects the system while still allowing accurate control and measurement.

When pressure builds, the diaphragm flexes. This movement pushes against a fill fluid or mechanical element on the other side. The pressure signal is transferred, but the fluid stays contained. That’s how diaphragm seals maintain both performance and cleanliness in sensitive or corrosive environments.

You’ll find diaphragms in dosing pumps, regulators, and metering systems. They help control flow rates, isolate components, and ensure repeatable pressure changes. Each cycle applies stress to the diaphragm. Without the right material and reinforcement, it can stretch, crack, or delaminate. That’s where custom design matters.

What Is a Custom Rubber Diaphragm?

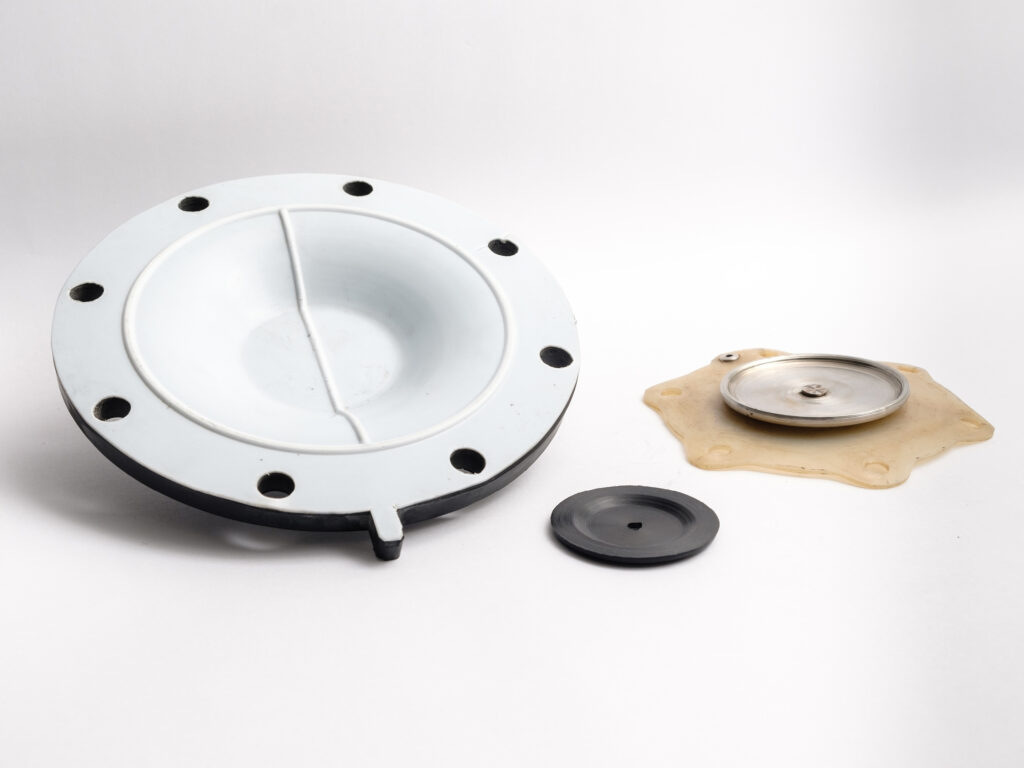

A custom rubber diaphragm is a flexible, pressure-responsive seal tailored to match specific application conditions. Unlike standard diaphragms, custom versions are built for exact material, thickness, and reinforcement requirements, which are based on how the seal needs to move, flex, and resist the surrounding environment.

These diaphragms are used in pressure-sensitive assemblies where off-the-shelf parts fall short. They maintain isolation under constant cycling, chemical exposure, and thermal variation. Typical rubber compounds without reinforcement can deform, wear out, or fail entirely. A diaphragm seal prevents that by holding pressure and flexing in a controlled way over thousands of cycles.

Rubber diaphragm seals are found in water systems, dosing pumps, chemical regulators, and industrial controls. They’re especially common in utilities, sanitary hardware, and pneumatic assemblies where movement, pressure, and isolation intersect.

Custom designs allow for reinforcement layers—such as cloth, metal, or plastic—to be added to the rubber, either inside or outside it depending on chemical exposure and mechanical demands. Engineers can adjust material hardness, wall thickness, or even layer positioning to get the durability and responsiveness they need.

A custom rubber diaphragm becomes the right solution when applications shift, regulations change, or standard parts can’t keep up. It solves the performance gap and extends system life without overhauling the whole assembly.

Typical Pressure Ranges and Application Environments

Rubber diaphragms operate across a broad pressure spectrum. They’re used in applications from a few pounds per square inch in low-pressure sensors to thousands of pounds per square inch in high-performance pumps. The design and material must account not just for pressure levels but also for how often and how fast those pressure levels cycle.

Diaphragms flex repeatedly to control flow and isolate sensitive components in lower-pressure systems, such as sanitary flush valves, air regulators, or chemical dosing pumps. These may cycle hundreds of times a day without visible wear. Higher-pressure environments—such as metering systems or industrial compressors—demand reinforced diaphragms that can resist extrusion, fatigue, and chemical attack over thousands of cycles.

We often see diaphragm seals used in:

- Water systems (toilets, pressure tanks, fire hydrants)

- Chemical injection and dosing systems

- Food processing equipment

- Pharmaceutical delivery systems

- Pneumatic controls and regulators

For applications involving food, potable water, or pharmaceuticals, diaphragm materials must meet strict regulatory requirements. Marco offers solutions that comply with:

- FDA 21 CFR §177.2600 for rubber articles used in repeated food contact

- USP Class VI for medical and biocompatibility standards

- USDA and FDA packaging guidelines for sanitary processing systems

Each environment introduces its own pressure, temperature, and chemical exposure profile. The diaphragm must be matched to all of them to ensure consistent performance and prevent premature failure.

What’s the Best Material for Your Rubber Diaphragm?

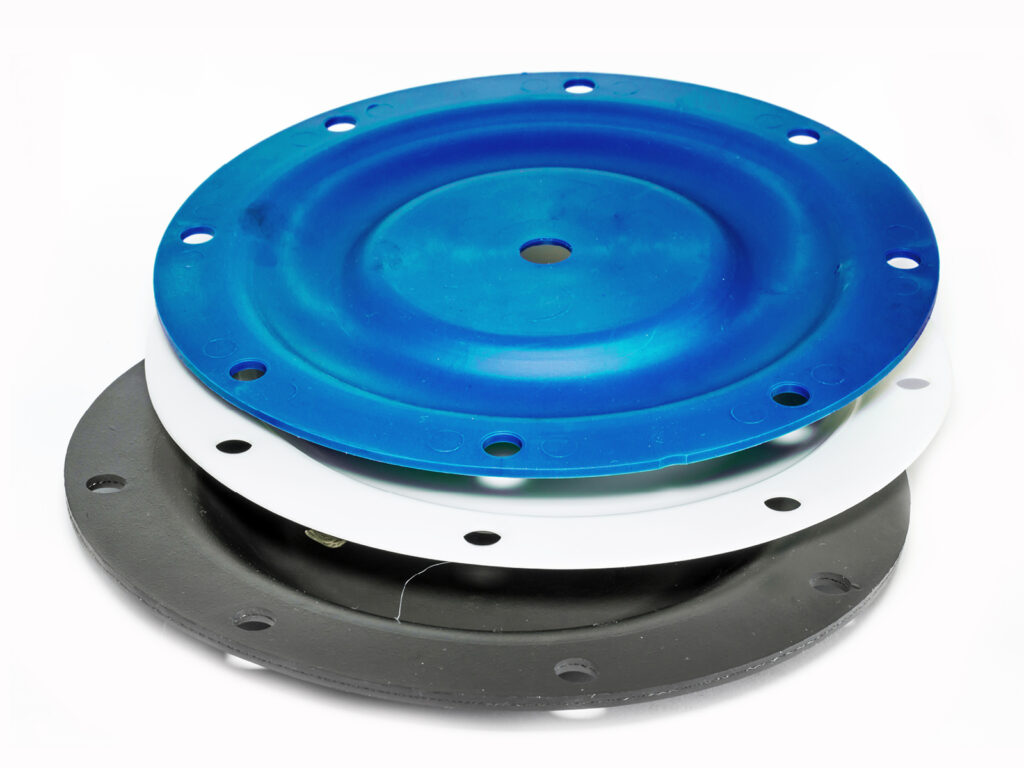

Material selection defines the life of your diaphragm and its performance under pressure, chemical exposure, and cycling. In most applications, the base elastomer isn’t enough. Diaphragms must be engineered with the right combination of rubber, reinforcement, and manufacturing process to match the system’s pressure, chemical media, and cycling demands.

Common diaphragm materials include:

- NBR (Nitrile): Strong resistance to oils and fuels; often used in low- to moderate-temperature applications.

- CR (Chloroprene): Good weathering and moderate chemical resistance.

- EPDM: Ideal for steam, water, and some chemicals; performs well in high-temperature environments.

- VMQ (Silicone): Excellent flexibility at low temperatures; good for food-grade and sanitary applications.

- FKM (Viton®): High resistance to heat and aggressive chemicals.

- PTFE: Maximum chemical resistance and thermal stability; used in demanding chemical processing and pharmaceutical environments.

The material alone isn’t the full story. Many diaphragms include reinforcements to improve strength, flexibility, and cycle life. These can include:

- Cloth inserts for durability over repeated flexing

- Kevlar layers for added tensile strength

- Metal or plastic reinforcements, molded or bonded to the diaphragm

- Internal or external reinforcement positioning, depending on exposure to process media

For example, external reinforcements reduce cost and simplify construction when the diaphragm doesn’t contact aggressive fluids. On the other hand, internal reinforcements stay protected by the rubber and are better suited for corrosive or high-pressure environments.

We also recommend considering the following parameters when choosing a material:

- Working temperatures

- Working pressure

- Burst pressure

- Working stroke distance

- Working chemical media

- Life cycles

Marco Rubber & Plastics evaluates all of these factors—media compatibility, pressure range, temperature, cycle frequency, and required compliance—when recommending a material. With access to over 3,600 rubber compounds and the ability to customize reinforcement layers and placement, we help teams get it right the first time.

Connection Types and Configurations

A diaphragm plays a critical role in connections. It isolates and seals a mechanical interface, usually between process fluid and instrumentation. Depending on the equipment design, that interface might be clamped, threaded, or welded. Without the diaphragm, the connection is exposed and vulnerable to contamination, corrosion, or fluid ingress.

The diaphragm fits into this connection and acts as a barrier. It separates process media from the sensors or actuators inside the system. This is essential in systems that handle aggressive chemicals, high-purity fluids, or pressure-sensitive instruments. The diaphragm blocks the fluid but allows the pressure to transfer cleanly.

Common configurations include:

- Clamped assemblies for easy removal and cleaning

- Threaded housings for compact, modular designs

- Welded units for permanent, high-integrity installations

At Marco, we support both legacy and new designs. Our team can reverse-engineer diaphragms from discontinued systems or damaged components, often without a drawing. We replicate performance-critical dimensions, materials, and reinforcement methods to restore functionality. When needed, we also design from scratch to meet tight specs, regulatory demands, and form-fit-function requirements.

Why Choose Marco for Custom Diaphragm Sealing Solutions?

When diaphragm performance drops, it’s rarely just wear and tear. Often, the environment has changed, and the material hasn’t kept up. That was the case for a customer using EPDM diaphragms in a sanitary water system. Their original seal had worked for years, but cycle life started dropping off. Equipment required more frequent maintenance, and failures were becoming harder to predict.

Marco’s team reviewed the application and analyzed the compound. As it turned out, the municipal water source had increased chloramine levels, which were degrading the EPDM. We adjusted the curing process, added a post-cure step, and validated a material that could handle the new chemistry. The customer saw a clear improvement in diaphragm life and avoided the cost of requalifying the entire system.

With access to over 3,600 compounds and in-house rapid prototyping, Marco delivers tailored diaphragm solutions without long lead times or oversized budgets. Our engineering-led approach includes:

- Reverse engineering legacy seals from samples or field-worn parts

- Material selection based on chemical-exposure, cycling, and compliance needs

- Design for die-cut, molded, cloth-reinforced, bonded, or PTFE-coated diaphragms

- Manufacturing options across the Shore A range, with tight tolerance control

Every diaphragm we deliver is built to solve a problem, not just fit a groove. The right seal prevents early failures, protects equipment, and extends system life. That’s why engineers across water systems, utilities, and OEM manufacturers turn to Marco when diaphragm performance matters.