Cutting and Sourcing Custom Gaskets: A Complete Guide

When you’ve got your gasket specs in hand, it may feel like the hardest part is behind you. But many buyers discover this is when the real challenge begins: getting the gasket made correctly and delivered on time.

Unlike o-rings, gaskets rarely come off the shelf. In fact, 80–90 percent are custom-made by necessity. That makes sourcing decisions critical. Choose the wrong approach, and you risk delays, wasted costs, and failures in the field.

This guide explains the process, outlines the trade-offs, and shows what matters most when cutting and sourcing custom gaskets.

Why Most Gaskets Are Custom

If you’re working with o-rings, you can usually flip through a catalog, match a size, and move on. That’s because o-rings are manufactured in a uniform circular design that fits standardized grooves across most equipment.

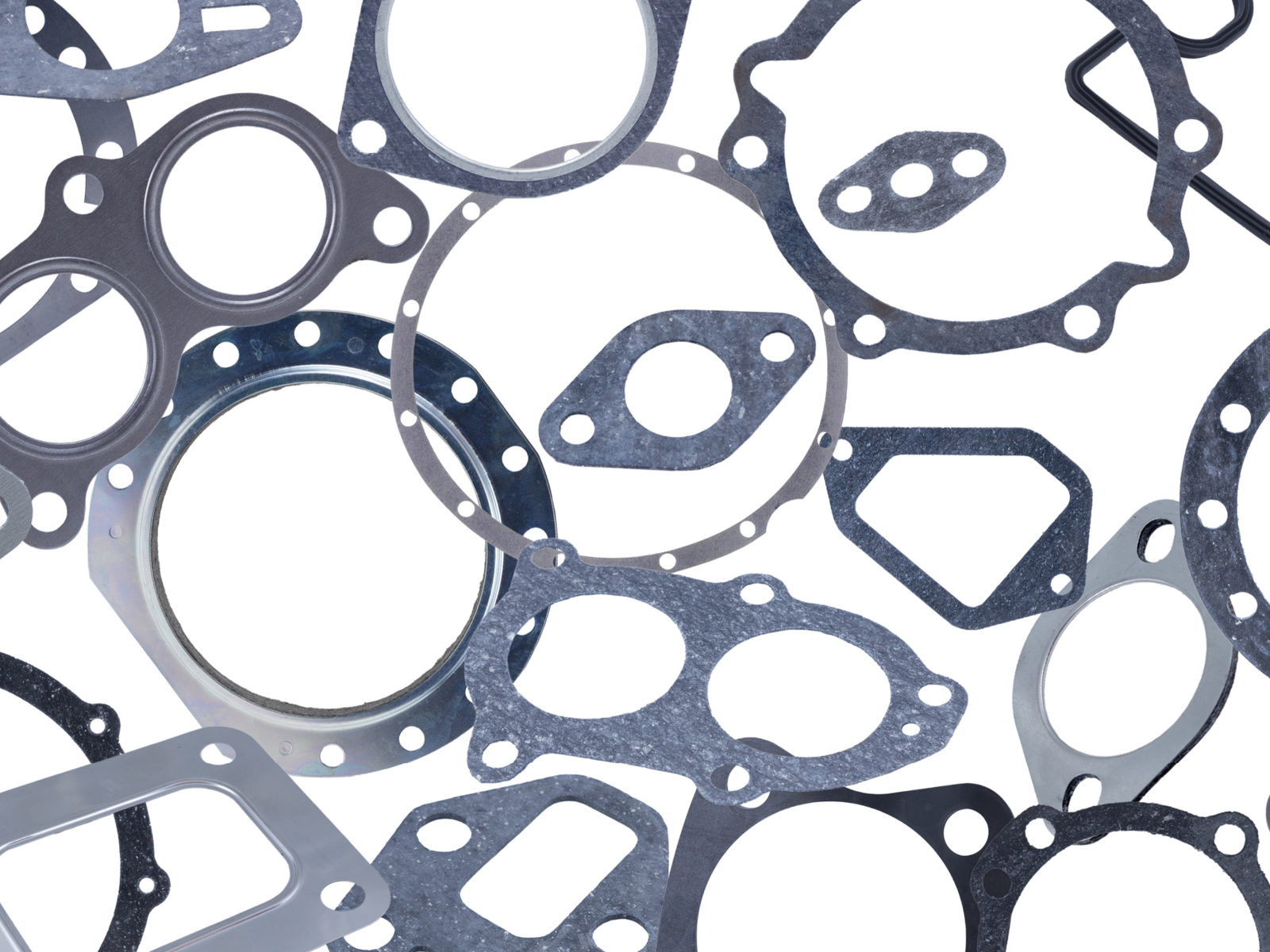

Gaskets are different. They often need to be cut or shaped to match specific bolt holes, irregular surfaces, or non-standard joints, especially in industrial setups where every mating surface can vary. Many gaskets also require complex cutouts to clear fasteners or fit around protrusions and must be made from materials that can withstand demanding conditions like extreme heat, aggressive chemicals, or cycling pressures.

There’s no universal catalog for gaskets. Fit, features, and materials must be tailored to the application. That’s why most are custom.

Cutting vs. Molding: Choosing the Right Process

In most cases, custom gaskets are either cut or molded. Both produce high-quality gaskets, but the right choice depends on your project details.

Cutting Custom Gaskets

Cutting removes the gasket shape from sheet or roll stock using custom die stamps, high-pressure water jets, or other cutting methods.

| Best Fit | Low to medium quantities, up to hundreds or thousands for smaller gaskets. Large quantities may be cost-prohibitive due to waste. |

| Advantages |

|

| Considerations |

|

| Ideal For | Prototypes, maintenance jobs, urgent replacements, or one-off designs that don’t justify tooling |

Molding Custom Gaskets

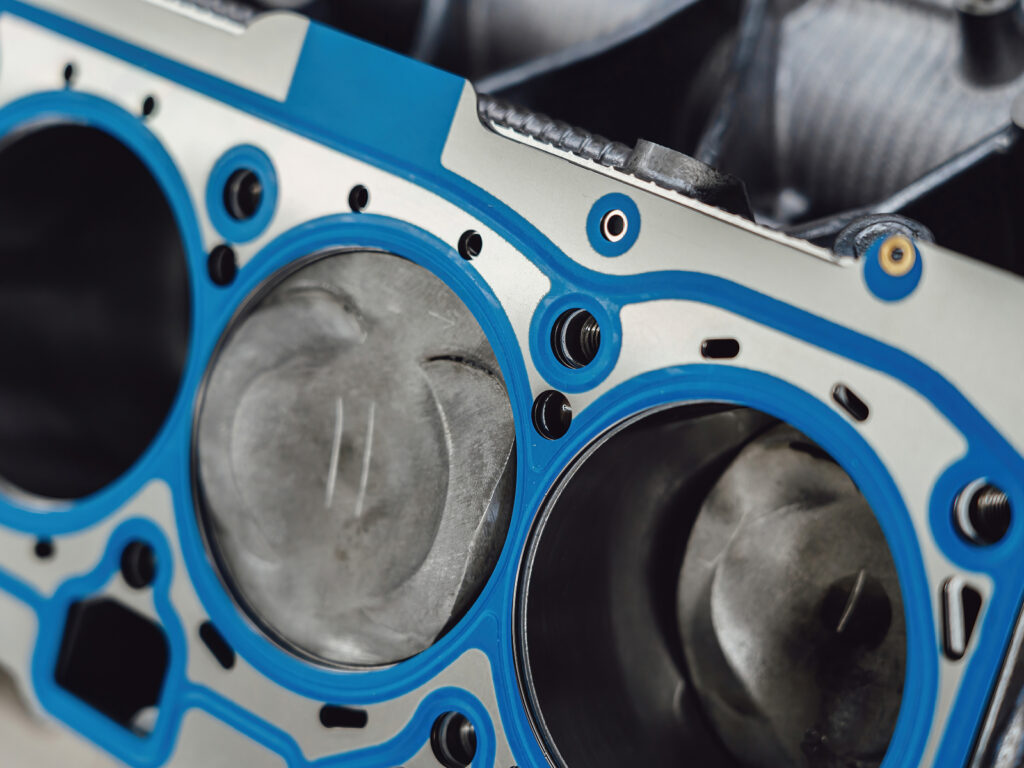

Molding creates gaskets by shaping raw elastomer in a custom tool under heat and pressure.

| Best Fit | Higher-volume runs, typically in the thousands. |

| Advantages |

|

| Considerations |

|

| Ideal For | OEM production, long-term programs, and repeat orders where scale justifies the tooling investment. |

Making the Choice: Molding vs. Cutting Custom Gaskets

There’s no single “best” method for custom gaskets. Cutting and molding both deliver reliable, durable seals. The difference is how well each process matches your needs.

| Quantity | Cutting suits small runs since there is no tooling. Molding pays off in large programs where the tooling cost is spread across thousands of parts. |

| Size & Geometry | Cutting handles complex/oversized parts with irregular shapes more easily. Molding delivers consistency at scale for simple, repeatable designs. |

| Urgency | Cutting delivers quick turnarounds from sheet stock. Molding is better for planned builds with longer timelines. |

| Cost Model | Cutting keeps upfront and small-run costs low. Molding reduces cost per part at scale, offsetting tooling costs over long runs. |

Common Cutting Methods for Custom Gaskets

If cutting is the right method for your gasket, there are several ways to do it, each with its own strengths. The two most common, and the ones most buyers are likely to encounter, are die cutting and waterjet cutting.

Die Cutting

Forms gaskets using a custom die. Requires tooling but is quick, repeatable, and cost-effective for high-volume, simple shapes.

Waterjet Cutting

Uses a high-pressure waterjet to cut gaskets directly from sheet stock. No tooling, highly versatile across materials and geometries; ideal for prototypes, smaller runs, and urgent needs.

Other Gasket Cutting Methods

Laser (for intricate shapes), lathe (for uniform rings), and kiss cutting (for adhesive-backed gaskets) are less common but support specific applications when required.

Why Sourcing Matters as Much as Cutting

For most engineers and buyers, the real challenge isn’t figuring out whether a gasket should be cut or molded, or knowing the ins and outs of each cutting method. It’s making sure the gasket you need shows up on time, in spec, and ready to perform.

Going direct to a cutter can mean chasing multiple quotes, getting inconsistent quality, or finding out too late that the shop can’t handle your material or tolerances. That’s where the right sourcing partner makes the difference.

Instead of spending time navigating manufacturers, a partner like Marco Rubber & Plastics

- Guides the cut-vs.-mold decision

- Recommends the right materials for your environment

- Matches you with the manufacturer best equipped for your needs

- Oversees compliance and quality control from start to finish

Marco’s advantage is a combination of experience, a broad vendor network, and fast delivery speed. That means no wasted time comparing options, second-guessing pricing, or wondering if your gasket will hold up.

What Drives Sourcing Decisions for Custom Gaskets

When it comes to gaskets, geometry is only part of the equation. The real sourcing decisions hinge on material, lead time, quantity, industry requirements, and how those factors overlap when it’s time to source your product.

Material Availability

Common elastomers like Viton®, Buna, EPDM, silicone, FFKM, and PTFE cover many applications. But specialty grades (FDA, USDA 3-A, USP Class VI, conductive, or EMI-shielding) are often critical in regulated or technical environments. Limited material access is a major sourcing bottleneck.

Urgency and Lead Time

Sourcing decisions often come down to speed versus efficiency. In a line-down situation, you need whatever process can deliver the fastest. For planned builds, cost and efficiency take priority, but only if the vendor can deliver on schedule.

Order Quantity

For flexibility and turnaround time, small runs are best handled through cutting. Large, repeat programs justify molding, which lowers per-part cost and reduces scrap. Knowing when to shift from one method to the other is key to balancing budget and output.

Industry Differences

Each industry has its own standards. Food and beverage requires sanitary, FDA-compliant materials. Aerospace demands precision and traceability. Oil and gas relies on elastomers that resist chemicals and decompression. Electronics often needs abrasion resistance or EMI shielding. Few manufacturers can meet these needs equally well, making vendor selection critical.

Each factor may seem straightforward on its own. But together, they turn gasket sourcing into a complex balancing act that can affect cost, schedule, and performance if not managed carefully.

The Cost of Getting It Wrong

Every sourcing decision carries weight. Choose the wrong partner, and the consequences ripple through your operation:

- Downtime that drains thousands of dollars per hour while equipment sits idle

- Contamination from the wrong material or stray debris that risks recalls, safety incidents, and regulatory penalties

- Waste in the form of scrap, rework, or unnecessary tooling

- QC failures that show up as rejected shipments, warranty claims, or in-field breakdowns

It takes only one gasket made from the wrong material or delivered too late to stall production and rack up costs. The right sourcing partner protects your schedule, budget, and reputation.

How Marco Gets It Right

Marco connects you to the best option for your application through a global network, broad material access, and fast, reliable delivery.

- Largest Vendor Network: With over a million SKUs across a global supply base, we’re not tied to a single shop or process. We match your project to the partner best equipped to deliver.

- Broad Material Access: Our network spans 3,000+ material formulations, from standard elastomers to FDA-, USDA-, and USP-approved compounds, so the right material is always within reach.

- Rapid Turnaround: Redundant supply chains in the US, Asia, and Europe allow us to prioritize urgent orders and deliver prototypes or short runs in days, not weeks.

- Quality Control Oversight: We manage every step, from vendor selection through final inspection, so defects are caught before they ever reach your floor.

- Flexibility at Every Scale: Whether you need a single gasket for a prototype, a short run for maintenance, or thousands of parts for OEM production, our growing network has the depth to deliver at any volume without compromising quality.

Get the Gasket You Need, When You Need It

One small gasket can stall a line, drive up costs, or put compliance at risk. Or it can do exactly what it’s designed to do: seal reliably, perform under pressure, and keep your operation moving. The difference comes down to making the right sourcing decisions from the start.

Marco combines the industry’s largest vendor network, broad material access, and proven speed to cut through the complexity and deliver a gasket that’s reliable, on spec, and on time.

Contact us today to source your next gasket. Need it fast? Ask about our expedited options.