Performance Seals Index

Our performance seals cover a range of applications across industries, operating under different temperatures, pressure thresholds, and chemical compatibility. Learn more about each type of performance seal and its characteristics and ideal applications below.

| Custom PTFE Seal and High Performance Plastics

|

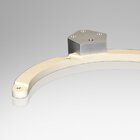

| PTFE Glide Rings and Cap Seals

|

2.jpg) | Back-up Rings for High Pressure

|

.jpg) |

|

| Oil Seals - Radial Shaft Seals

|

Ready to Seal Your Success with Marco Rubber & Plastics?

Marco Rubber & Plastics has the capacity to create seals in the custom shapes, materials, and sizes your application needs to the highest quality standards. Connect with one of our experts and discuss your needs today.

(2).jpg)

2.jpg)